Smart wareshoue makes industry smarter

World’s Leading Autonomous Pallet Robot Company

“Pallet-to-Person” Storage and Picking Solution

Based on diverse storage needs, industry sectors, application scenarios, and warehouse sizes, we offer tailored autonomous storage solutions.

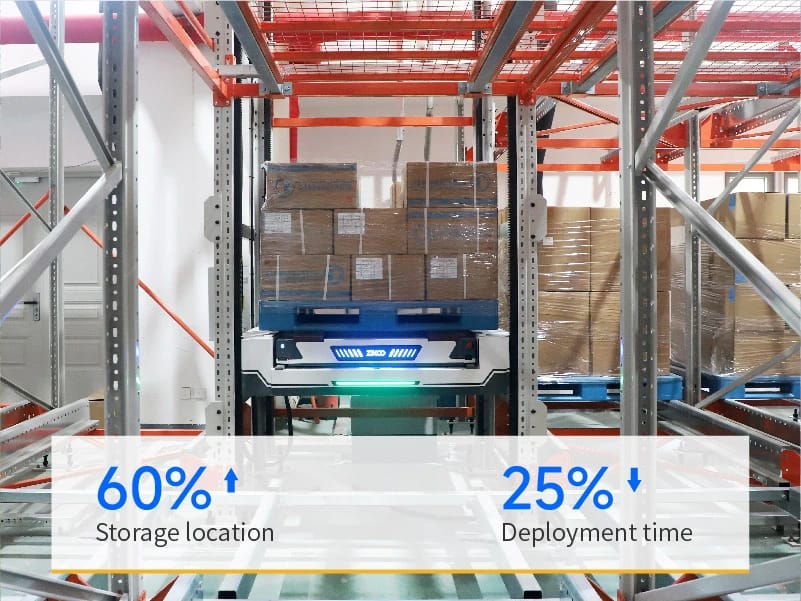

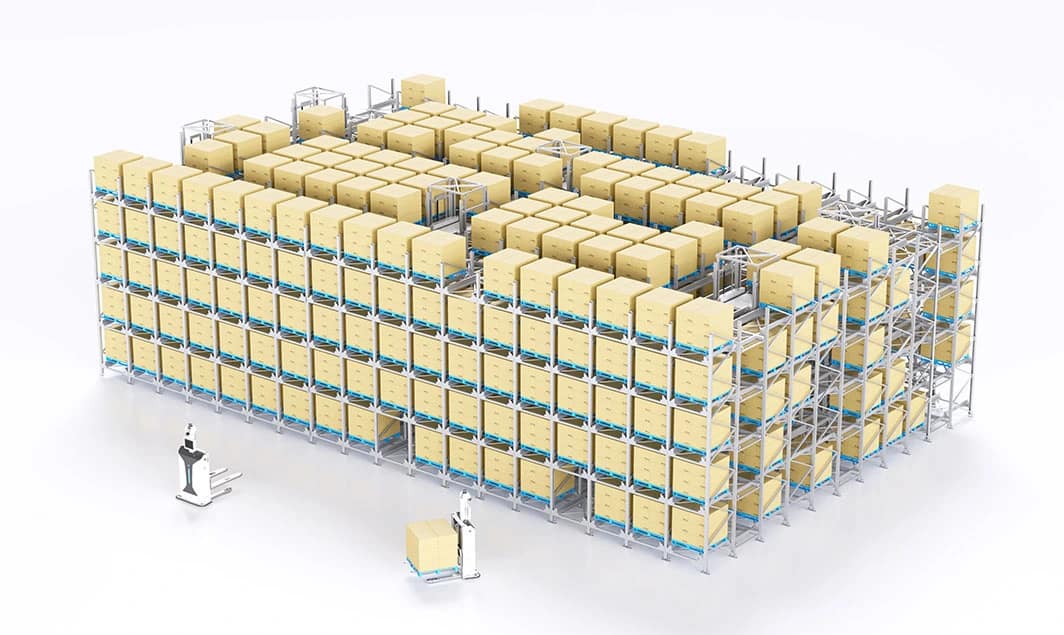

Six-Way Shuttle Dense Storage System

The innovative combination of R-bot four-way shuttle…

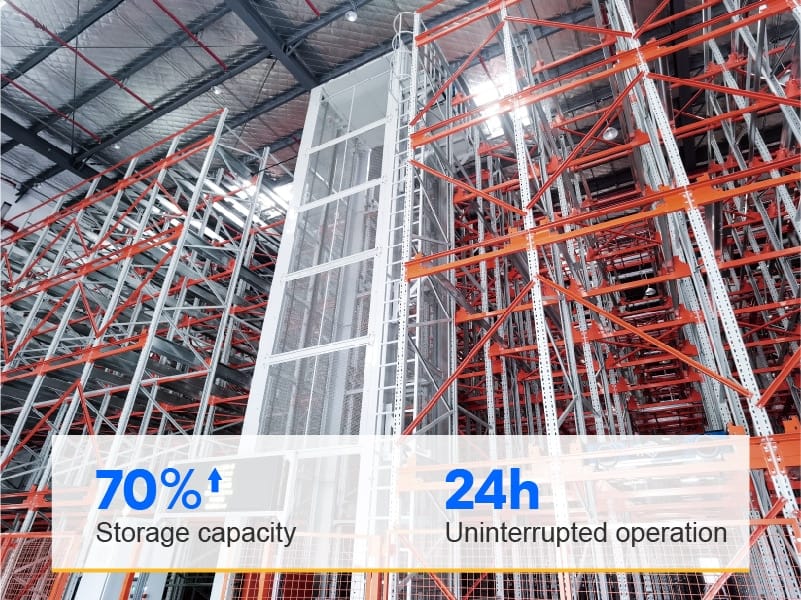

Six-Way Shuttle Storage & Picking System

Through the flexible deployment of H-bot vertical two-way …

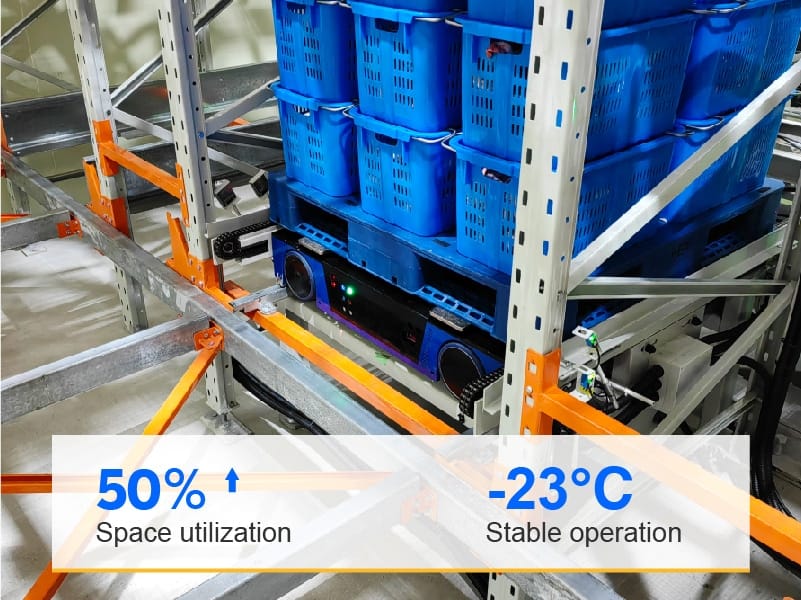

Narrow aisle storage system

The U-bot High-Efficiency Dense Storage and Picking System…

Narrow aisle picking system

The narrow aisle picking system composed of U-bot + AMR …

TALK TO OUR EXPERT

Our Service

Pre-Sales Planning

Our pre-sales planning process encompasses several key steps: customer research, needs analysis, solution design, and simulation validation.

Detailed Design

Our detailed design phase includes the following components: blueprint decomposition, interface integration.

Design and Manufacturing

In the design and manufacturing stage, our work encompasses software development, and software testing.

Installation and Commissioning

During the installation and commissioning phase, we will enter the site to install the autonomous storage equipment and fine-tune the software, ensuring everything is set up to your satisfaction.

Acceptance and Delivery

On the acceptance and delivery phase, we conduct operational testing, provide training for your staff, and ensure they are fully equipped to use our smart storage products.

After-Sales Service

We offer regular after-sales service, including 24/7 technical support, routine inspections, and systematic maintenance to ensure continuous and optimal performance of the smart storage system.

Case Studies

We have served over 300 clients and implemented more than 400 projects, with our business extending across all of Asia. Our smart storage robots have not only excelled in the domestic market but have also made significant inroads into international markets.

Q&A

We Offer A Wide Range Of Services And Solutions

What is the delivery timeline for the ZIKOO four-way shuttle racking system project?

The delivery timeline ranges from 3 to 6 months, depending on the project size and level of customization required. Typically, the delivery period for standard projects is around 3 months.

What are the advantages of the four-way shuttle racking system compared to traditional warehouses?

The four-way shuttle racking system offers several advantages over traditional warehouses, including high-density storage, full utilization of warehouse space, automation and intelligent operations, high accuracy in operations, reduced labor costs, flexible deployment based on site conditions, and scalable configurations to meet efficiency demands. These features help businesses reduce costs and enhance efficiency.

How does ZIKOO compare to other four-way shuttle brands in terms of advantages?

Compared to other brands, ZIKOO maintains a customer-centric approach and offers several strengths, such as robust robot product technology, advanced software scheduling capabilities, professional warehouse planning expertise, extensive experience with industry benchmark projects, and a comprehensive after-sales service system. ZIKOO continuously creates value for customers by driving cost reductions and increasing efficiency.

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-19941778955