As a leading enterprise in the automobile manufacturing industry, an auto parts manufacturer in Suzhou cooperate with Zikoo to implement a complete set of intelligent warehouse solutions to build a three-dimensional warehouse for parts. Through multi-robot automatic and collaborative operations across floors, it realizes cross-factory transportation from production to storage. The informatization, automation, and intelligence of the process will increase the storage capacity by 70%, increase the operating efficiency by 80%, and improve the level of warehouse management.

Project background

With the promotion of national policies and the development of the Internet economy, the scale of the auto parts industry is also expanding. At the same time, auto parts have the characteristics of a large variety, different specifications, and a short product life cycle. In this context, the traditional warehousing mode of auto parts warehousing and logistics has become a bottleneck. Factors such as low space utilization and low intelligence have led to low overall warehousing efficiency. At the same time, operating costs remain high, which is far from meeting existing needs.

Therefore, auto parts manufacturers urgently need to seek new breakthroughs to cope with the industry’s flexible, intelligent and highly integrated intelligent manufacturing system to achieve cost reduction and efficiency increase.

Solution

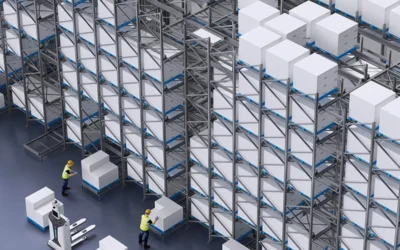

Zikoo built a 5-floors four-way pallet shuttle automated stereoscopic warehouse with an area of 2973 ㎡. It adopts the pallet storage method and custom-installs multi-deep shelves for four-way shuttle. It is equipped with 7 Smart four-way pallet shuttles and 6 high-speed Elevators and flexible conveying line equipment are deployed with WMS and WCS software systems.

According to the order task quantity and actual operation status of the smart four-way pallet shuttle, the multi-layer and multi-region four-way pallet shuttle will be intelligently dispatched ,not only can docking production lines be operated 24 hours a day without interruption, but also material informationization and refined management and control can be realized.