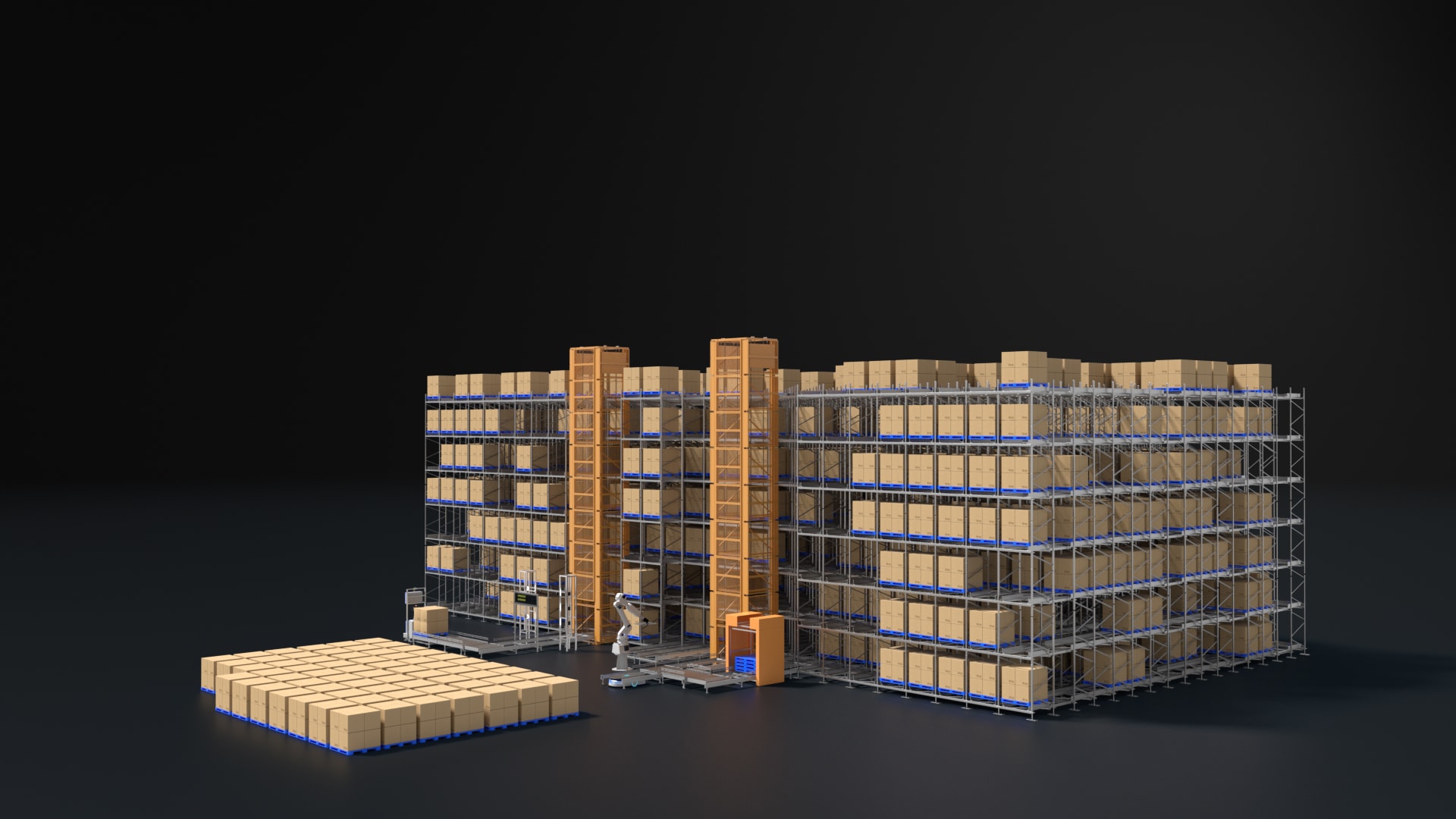

r-bot+h-bot

dense storage system

R-bot+H-bot dense storage system is suitable for the whole pallet in/out or a small amount of picking in/out scenarios. Compared with stacker cranes AS/RS, the storage density and comprehensive efficiency are greatly improved, with the advantages of high efficiency, high density, high flexibility, quick delivery and so on, which is the best choice for the customers in pursuit of the maximum storage density and improvement of the space utilization rate.

The Advantages of R-bot+H-bot dense storage system

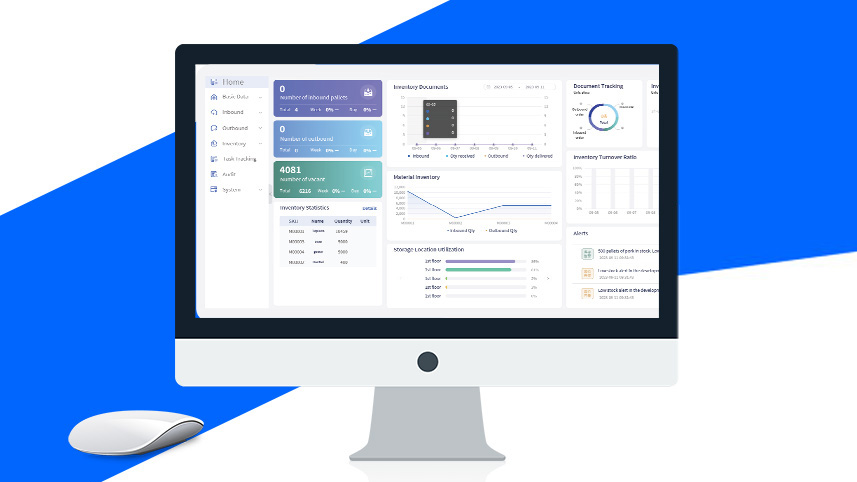

R-bot dense storage system, using R-bot four-way shuttle and H-bot high-speed elevator horizontal and vertical combination of operations, combined with PTP smart warehousing software, to achieve the maximum degree of dense storage, space utilization rate is very high. The system is not restricted by fixed routes and can reach any position in the space. It can also flexibly increase or decrease the number of four-way shuttles according to the business requirements, and can be flexibly matched with conveyor lines and AMR to complete the rapid in and out of the warehouse.

High Efficiency

- Comprehensive efficiency increase of 2-3 times compared to traditional warehouses, and 15%-20% compared to ordinary automated three-dimensional warehouses (stacker cranes AS/RS)

High Density

- The storage density is 4-6 times higher than in traditional warehouses and 30-100% higher than in ordinary automated three-dimensional warehouses (stacker cranes AS/RS)

High Flexibility

- Suitable for new or renovated warehousing scenes, suitable for multiple pillars, cross-floor, irregular warehouse types, according to the business needs of the change in the number of flexible increase or decrease in the number of equipment

Quick Delivery

- Reduction of delivery times by more than 40 % in comparison to ordinary automated three-dimensional warehouses (stacker cranes AS/RS), resulting in high quality deliveries

In Action

Receiving Process

Dispatch Process

Features and Benefits

Data Simulation

- Net size of warehouse: L60m*W20m*H30m

- Product portfolio R-bot*6 H-bot*2

- No. of storage positions 2984

- Applicable SKUs ≤10000

- Efficiency of in/out storage ≥100 pallets/hour

- Investment amount USD 600,000+

Connect with our experts to receive customized robotics solutions

Applications

Scenarios

Industries

Case Studies

Jointown Pharmaceutical

Pain points: Under new requirements, the company set an overall processing volume of 10,000 pieces/hour with 99.9% accuracy.

Solution: Picking robots transport goods directly to the platform for unmanned unloading. User friendly interface providing multiple data gathering, reducing operation risks and increasing transportation safety.

1/3increased 1400per hour

storage capacity outbound

Composition

Connect with our experts to receive customized robotics solutions

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-13851470374