In today’s logistics landscape, warehouse efficiency and space utilization are critical, especially for companies aiming to enhance operational performance. Smart warehouse solutions have become essential, and ZIKOO ROBOTICS has focused on developing intelligent automated storage solutions for palletized goods, with its core product being the innovative four–way pallet shuttle.

Why Choose the Four-Way Pallet Shuttle?

As more companies move towards smart warehouse solutions, the limitations of traditional storage systems become apparent. Physical constraints, such as warehouse area, height, and layout, combined with unpredictable market demands, lead businesses to seek flexible, automated storage solutions. In contrast to conventional automated storage and retrieval systems (AS/RS), smart warehousing companies today prioritize automated pallet storage systems that offer high adaptability and intelligence.

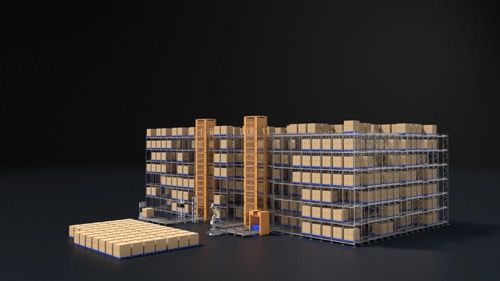

The four-way pallet shuttle has become a preferred choice for dense automated storage, thanks to its flexibility in movement, autonomous handling, and multi-vehicle collaboration capabilities. This advanced smart solutions warehouse technology overcomes the limitations of two-way shuttles and mother-child shuttles by enabling free movement in all four directions. Paired with lifts, it can access any position within a multi-level racking system, maximizing storage density and space utilization.

Advantages of the Four-Way Shuttle

The four-way pallet shuttle by ZIKOO ROBOTICS is continually refined to meet the growing demands for smarter, automated storage solutions. It not only enhances storage density but also supports efficient workflows across multiple applications, such as order picking and inventory transfers. Key benefits include:

- High Storage Density

- Scalability

- Rapid Deployment

- Flexible Layout

- Eco-Friendly Efficiency

Applications of the Four-Way Shuttle

With excellent versatility, the four-way pallet shuttle is suitable for a range of operational needs, from high-frequency transactions to low-frequency storage. This smart solutions warehouse technology complements traditional AS/RS and is especially valuable in the following sectors:

- Manufacturing: Supports storage of raw materials, line-side inventory, and finished goods, enhancing workflow efficiency.

- Distribution: Ideal for regional distribution centers and production warehouses, optimizing distribution processes.

- Logistics & 3PL Centers: Improves efficiency in third-party logistics operations by streamlining warehouse storage and retrieval.

- Cold Chain and Specialized Warehousing: Performs exceptionally in cold chain environments and securely stores fragile or high-value items.

Conclusion

As a leading manufacturer in the four-way pallet shuttle industry, ZIKOO ROBOTICS continuously increases its investment in R&D to maintain its position at the forefront. We understand that as demand for efficient, flexible, and eco-friendly warehousing solutions grows in the logistics sector, only through ongoing innovation and product enhancement can we stand out in the competitive market.

Keywords: