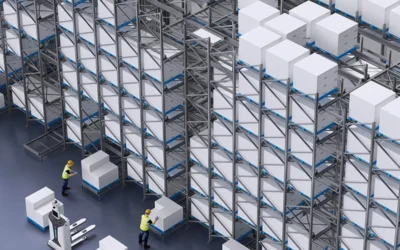

In today’s fast-paced logistics environment, warehouse management faces significant challenges in maintaining both precision and efficiency. Traditional warehouse operations heavily rely on manual labor, which increases the risk of human errors and inefficiencies, ultimately affecting overall warehouse productivity. However, with the advancement of warehouse automation, four-way shuttle systems have emerged as a powerful solution to improve both accuracy and efficiency in warehouse operations.

Precision Challenges in Warehouse Management

Manual processes in warehouse management often lead to errors such as misplaced inventory, incorrect order picking, and slow product retrieval. These issues not only reduce the efficiency of operations but can also lead to customer dissatisfaction. With the rise of intelligent warehousing, automated systems like the four-way shuttle are helping to address these challenges by providing more precise and efficient solutions.

Core Advantages: Enhancing Precision and Reducing Errors

1.High-Precision Location Systems

A key feature of the four-way shuttle is its advanced navigation system, which may include technologies like RFID, laser guidance, and computer vision. These systems enable the shuttle to precisely navigate the warehouse, ensuring accurate storage and retrieval of goods. By reducing reliance on human intervention, automatic equipment like the four-way shuttle significantly decreases the chances of errors caused by manual handling.

2.Intelligent Scheduling

Through the use of smart algorithms, four-way shuttle systems are capable of optimizing their movement paths in real-time. This optimization ensures that the shuttle operates in the most efficient way possible, reducing travel time and improving overall task completion speed. With warehouse automation driving these processes, the shuttle can operate continuously without human involvement, maintaining high levels of precision and reducing errors associated with manual processes.

The Role of Four-Way Shuttles in Warehouse Management

The integration of four-way shuttle systems in warehouse management provides a host of benefits. These systems improve inventory accuracy by ensuring that items are stored and retrieved exactly where they are needed, eliminating the risk of misplaced goods. Furthermore, they automate the order picking process, reducing human error and speeding up the fulfillment cycle. By ensuring more accurate and timely stock management, these automated systems contribute to smoother operations and improved customer satisfaction.

Choosing the Right Four-Way Shuttle Manufacturer

To maximize the benefits of warehouse automation, it’s crucial to select a reliable and experienced four-way shuttle manufacturer. A top-tier manufacturer, such as Zikoo Robotics, provides cutting-edge intelligent warehousing solutions that integrate seamlessly with existing warehouse management systems (WMS). With years of expertise and a track record of delivering high-performance automatic equipment, partnering with a leading manufacturer ensures that your warehouse operations benefit from the latest technological innovations.

Conclusion: Dual Improvement in Precision and Efficiency

In conclusion, adopting four-way shuttle systems for your warehouse management needs offers a substantial improvement in both precision and efficiency. With features like high-precision navigation and intelligent scheduling, these systems reduce human errors and optimize operations. By collaborating with four-way shuttle manufacturers like Zikoo Robotics, you can unlock the full potential of your warehouse, achieving higher accuracy, faster order fulfillment, and smarter inventory management. Transitioning to automated warehouse solutions will help you streamline operations and stay ahead in today’s competitive logistics landscape.

Keywords:four-way shuttle,Four-way shuttle manufacturers,Warehouse automation,automatic equipment,Intelligent Warehousing