Introduction

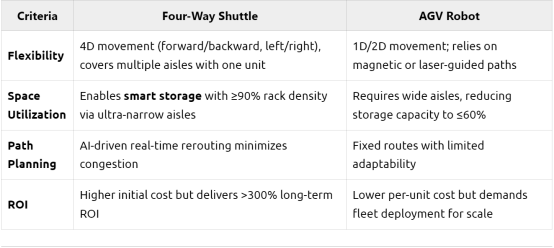

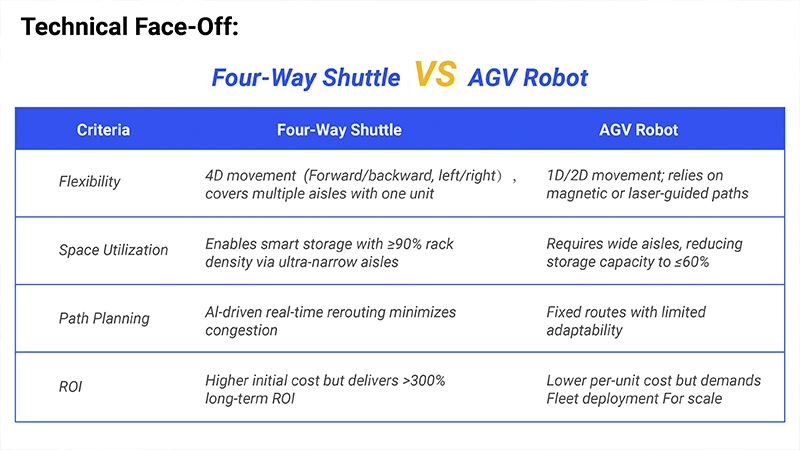

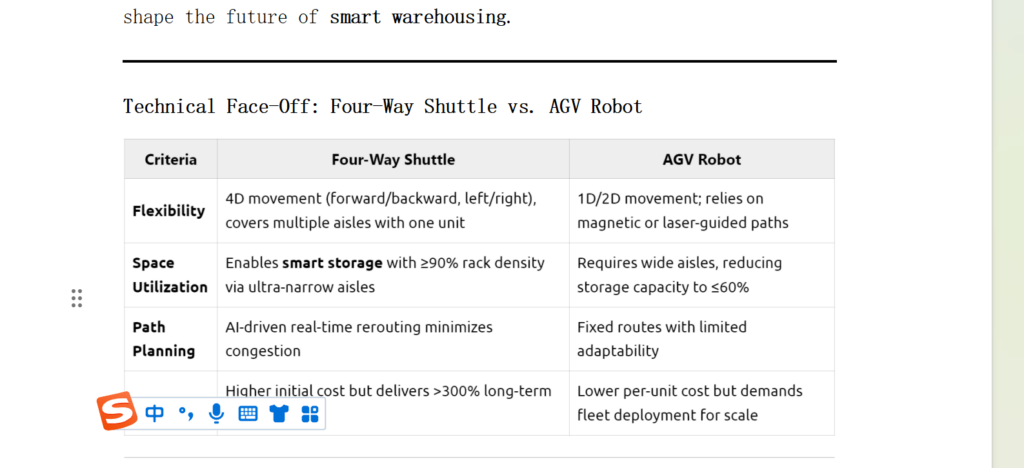

The Four-way shuttle and AGV robot are frequently compared in warehouse automation discussions, but their distinct strengths in efficiency, flexibility, and ROI reveal unique strategic value. While AGVs dominate rigid workflows, four-way shuttles excel in smart storage optimization. This warehouse automation comparison explores how these technologies shape the future of smart warehousing.

Application Scenarios: Where Each Shines

1.Four-Way Shuttle:

- High-Value, SKU-Intensive Environments:

Ideal for pharmaceutical cold storage (e.g., -25°C vaccine warehouses) and electronics micro-fulfillment centers requiring dynamic smart storage adjustments. - E-Commerce Hubs: Rapidly adapts layout during peak seasons using intelligent path planning.

2.AGV Robot:

- Heavy-Duty, Fixed Workflows:

Dominates automotive assembly lines for moving heavy components (1+ tons) along predefined routes. - Large-Scale Distribution: Efficient in standardized layouts with predictable material flows.

Strategic Recommendations for Warehouse Automation

- Hybrid Solutions for Maximum ROI:

Integrate AGV robots for horizontal transport (e.g., raw material delivery) with four-way shuttles for vertical storage and order picking. For example, Zikoo Robotics’ hybrid systems improve throughput by 45% in 3PL facilities by merging AGV efficiency with shuttle precision.

2.Prioritize Customization:

Choose four-way shuttle providers like Zikoo Robotics offering specialized designs:

- Extreme Cold Adaptation: -25°C models for frozen food or biotech storage.

- Explosion-Proof Options: Safe handling in chemical or hazardous environments.

3.Future-Proof Tech Integration:

Opt for systems compatible with IoT platforms and WMS/ERP software to streamline smart warehousing operations.

Why Zikoo Robotics Stands Out

As a leader in smart warehousing innovation, Zikoo Robotics redefines warehouse automation comparison benchmarks:

- Patented Multi-Agent Systems: Ensures seamless coordination between shuttles and AGVs in hybrid setups.

- Proven Industry Expertise: Dominates regulated sectors like pharmaceuticals (GDP compliance) and cold chain logistics.

- 24/7 Global Support: Resolves 98% of technical issues within 4 hours, minimizing downtime risks.

Keywords:Four-way shuttle、AGV robot、Warehouse automation comparison、Smart storage、Smart warehousing