Introduction

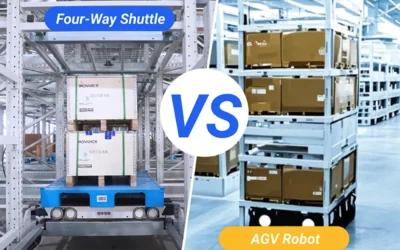

The rapid growth of e-commerce and manufacturing has intensified pressure on warehouses, with limited space, operational inefficiencies, and picking inaccuracies emerging as critical bottlenecks. Enter the four-way shuttle, a game-changing intelligent logistics equipment that leverages adaptive design and AI-driven coordination to unlock the potential of high-density warehousing. As a cornerstone of warehouse automation, this innovation reshapes smart warehousing by optimizing space, speed, and flexibility.

Challenge 1: Space Constraints

Traditional warehouses often waste over 40% of vertical space due to fixed rack heights and aisle layouts. The four-way shuttle revolutionizes storage by operating in ultra-tall racking systems (up to 20 meters), tripling vertical capacity. Unlike conventional vehicles bound to specific aisles, these shuttles navigate freely in all four directions—forward, backward, left, and right—to access any pallet or bin.

Zikoo Robotics, a leader in intelligent logistics equipment, enhances this efficiency with its patented “3D Clustering Algorithm,” enabling warehouses to store 3x more SKUs without expanding footprints.

Challenge 2: Operational Inefficiency

Legacy systems require multiple vehicles for different aisles, resulting in idle time and delayed workflows. The four-way shuttle eliminates this limitation by autonomously crossing aisles. For example, Zikoo Robotics’ shuttles prioritize high-demand items during peak seasons, accelerating task response rates by 50% and handling 1,200+ operations per hour. Integrated with warehouse automation networks, these systems synchronize with robots and conveyors, reducing labor costs by up to 60%.

Challenge 3: Inflexible Layouts

Seasonal demand surges often force warehouses to redesign storage zones manually. The four-way shuttle adapts dynamically, using real-time data to reconfigure paths instantly. Zikoo’s systems analyze ERP/MES data to auto-adjust inventory placement, ensuring 99.9% picking accuracy while supporting mixed storage of pallets, bins, and irregular items. This flexibility slashes reconfiguration costs by 35%, empowering businesses to pivot swiftly in volatile markets.

Technical Innovations Driving Smarter Warehousing

1.Multi-Format Compatibility:

Zikoo Robotics’ four-way shuttles handle pallets, mini-loads, and custom containers seamlessly, eliminating redundant equipment investments.

2.System Integration:

As pioneers of smart warehousing, Zikoo ensures plug-and-play connectivity with ERP, WMS, and IoT platforms, boosting inventory turnover by 25%.

3.Sustainability Focus:

Energy-efficient lithium batteries and regenerative braking cut power consumption by 40%, aligning with green supply chain goals.

Choosing the Right Four-Way Shuttle Provider: Key Criteria

1.Technical Expertise:

Prioritize providers with custom R&D capabilities, like Zikoo’s patented multi-agent scheduling systems, to tackle complex workflows.

2.Proven Success:

Demand case studies from regulated industries—such as pharmaceuticals or cold chain logistics. Zikoo’s -25°C shuttles dominate vaccine storage, achieving 100% compliance with GDP standards.

3.Reliable Support:

Opt for providers offering 24/7 remote diagnostics and rapid onsite assistance. Zikoo’s global service network resolves 98% of issues within 4 hours, minimizing downtime risks.

Conclusion

The four-way shuttle is redefining high-density warehousing, transforming space limitations, inefficiencies, and rigidity into strategic advantages. For businesses seeking intelligent logistics equipment that integrates advanced warehouse automation and smart warehousing strategies, Zikoo Robotics stands out with its innovation-first approach.

Elevate your warehouse from a cost burden to a growth accelerator—choose Zikoo Robotics for future-proof logistics excellence.

Keywords:Four-way shuttle、High-density warehousing、Intelligent logistics equipment、Warehouse automation、Smart warehousing