As global supply chains increasingly demand both efficiency and environmental sustainability, the four-way shuttle has become a core component of automated pallet storage and intelligent warehousing solutions. With its highly efficient and flexible operation, as well as its eco-friendly energy-saving features, it is becoming the preferred technology for modern warehouse upgrades. Here are key ways in which four-way shuttle help businesses achieve automated racking systems and sustainable development:

1. High-Density Storage: Maximizing Warehouse Space Utilization

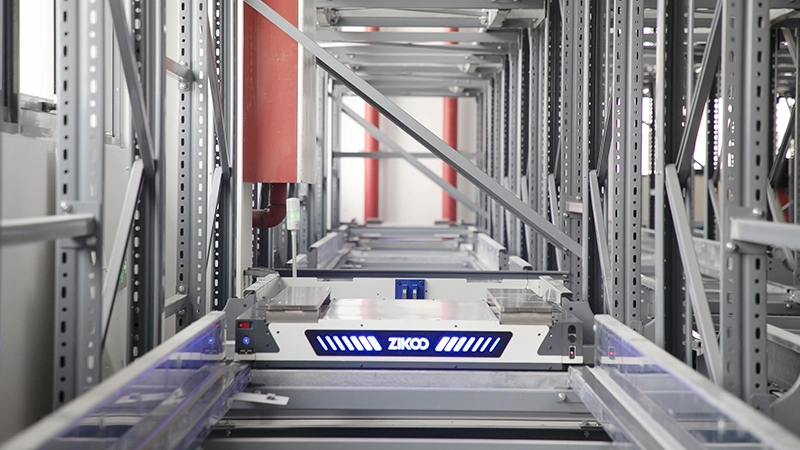

The four-way shuttle can move flexibly in all four directions within multi-tier shelving, fully utilizing both vertical and horizontal spaces in the warehouse. Compared to traditional storage systems, its design significantly increases storage capacity per unit area.

This automated pallet storage system helps businesses optimize warehouse layouts, reducing the need for new warehouses. This not only saves land resources but also lowers carbon emissions during warehouse construction, aligning with the goals of green warehousing development.

2. High Efficiency and Energy Saving: Driving Green, Low-Carbon Warehousing

The four-way shuttle is equipped with an advanced battery management system and energy recovery technology, ensuring low energy consumption during operation.

- Energy Recovery Technology: During braking and deceleration, kinetic energy is converted into electrical energy for storage, further reducing energy waste.

- Advantages Over Traditional Equipment: Compared to traditional forklifts, the four-way shuttle is more energy-efficient and reduces energy waste caused by human operation.

The low-energy design of the four-way shuttle makes it an essential device for intelligent warehousing companies in building low-carbon supply chains.

3. Fully Automated Operation: Improving Efficiency and Accuracy

By integrating with automated racking systems and intelligent warehousing software (WMS, WCS, RCS), the four-way shuttle enables full-process automation from inbound to outbound operations.

- Reduces human intervention, lowering the risk of product damage and resource waste caused by human error.

- Increases order processing speed, especially in e-commerce and fast-moving consumer goods (FMCG) sectors, meeting the demand during peak periods.

4. Flexible Solutions for Multiple Industries

As a crucial part of modern intelligent warehousing solutions, the four-way shuttle is widely applied in industries such as food cold chains, e-commerce, pharmaceuticals, and manufacturing due to its modular design and high adaptability.

- Modular Design: Easy to maintain and upgrade, extending the equipment’s lifespan and reducing the environmental impact of equipment disposal.

- High Flexibility: Supports the storage needs of various types of goods, efficiently handling everything from lightweight daily items to heavy industrial products.

The four-way shuttle, with its efficiency, energy-saving, and flexibility, provides businesses with powerful intelligent warehousing solutions. It not only enhances warehouse operational efficiency but also helps companies practice green development while achieving high-density storage.

As a leading intelligent warehousing company, ZIKOO SMART TECHNOLOGY CO., LTD. will continue to drive innovation in four-way shuttle technology, offering smarter, more eco-friendly warehousing services to global enterprises, and jointly creating the green supply chain ecosystem of the future!

Keywords: Four-Way Shuttle , Automated Pallet Storage, Automated Racking Systems, Intelligent Warehousing Solutions, Intelligent Warehousing Company

Keywords:

four-way shuttle