· 30% faster order response.

· 10% lower project budgets.

· Warehouse renovation in less than 3 months.

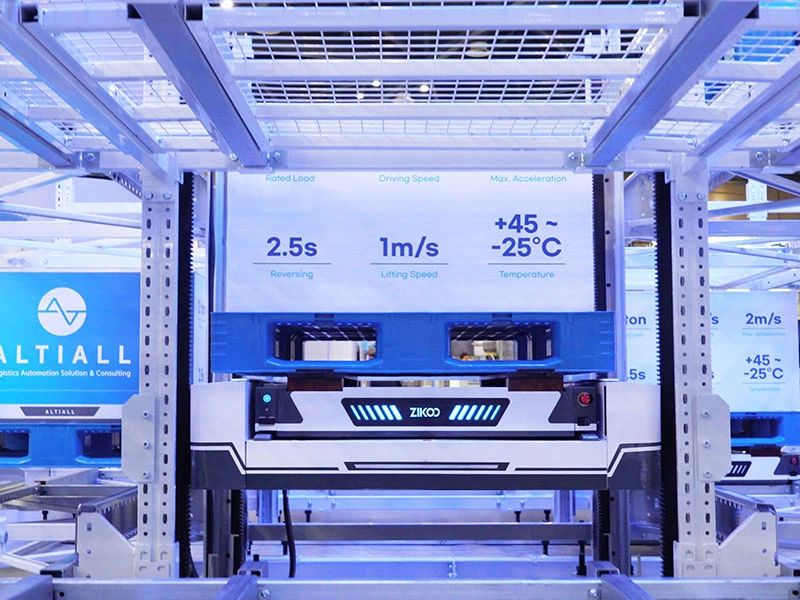

These once-impossible demands are now achievable thanks to the launch of Zikoo Robotics’ game-changing Six-way shuttle—the next-generation solution redefining Intelligent Warehousing Solutions in 2025. With over 200 inquiries just one month after release, this innovation is capturing the attention of logistics experts worldwide.

Here are 8 must-know Q&As that unveil why this product is redefining modern Automatic 3D warehouse logistics.

Q1: Why is the Six-way Shuttle a Standardized Product?

A: Unlike traditional lifters or customized systems, Zikoo’s Six Way Shuttle Solutions are Standardized Intelligent Devices. The shuttles are pre-engineered for mass production and rapid deployment, cutting cost and lead time significantly. Each unit undergoes rigorous 200-day full-load tests and 72-hour QC before delivery.

Q2: How is on-site failure managed?

A: The system is modular: a Four-way shuttle for horizontal movement, paired with a vertical unit. In case of failure, built-in hoists lift the faulty unit for removal. Vertical issues can be resolved with rescue rails and safe manual pallet transfer—ensuring fast and secure maintenance access.

Q3: What’s the cost advantage over traditional lifts?

A: A standard 10m traditional lifter costs ¥180–200K; Zikoo’s vertical shuttle costs just ¥130–150K—a 30% reduction. It eliminates complex frames and on-site wiring, offering unmatched value in High Density Storage Devices.

Q4: How long does installation take?

A: One Six-way shuttle (1 horizontal + 1 vertical unit) installs in just 4–5 hours with a 2-person team—ideal for time-sensitive projects.

Q5: Does long-term load affect rack integrity?

A: Not at all. Vertical loads are absorbed by the ground. Horizontal forces are minimal and structurally balanced through beam reinforcements. Testing confirms negligible deformation, keeping the Automatic 3D warehouse system fully stable.

Q6: Isn’t the vertical unit slower than traditional lifts?

A: Not really. While traditional lifts can reach 1.2–1.5m/s, most operate below 1m/s due to load safety. Zikoo’s vertical units maintain that range while ensuring safer, more consistent performance.

Q7: How many devices can be coordinated simultaneously?

A: Zikoo’s cluster scheduling system supports intelligent warehousing coordination without device limits. It uses dynamic path optimization across the warehouse’s 3D map. Capacity depends on your site layout—Zikoo provides full planning support.

Q8: Can I switch from a Four-way Shuttle + Lifter to a Six-way Shuttle plan?

A: Absolutely. Zikoo can convert existing designs to a Six Way Shuttle Solution without compromising storage or throughput. If your RFP includes flexibility for equivalent specs, Zikoo’s solution offers significant per-location cost advantages.

Why Zikoo?

Zikoo Robotics is a pioneer in Intelligent Warehousing, specializing in modular, scalable, and high-performance automation. From Four-way shuttle evolution to advanced Six-way shuttle systems, Zikoo delivers Intelligent Warehousing Solutions built for the next generation of supply chains.

Ready to transform your warehouse?

Contact Zikoo for a personalized design assessment and demo.

Keywords:Intelligent Warehousing Solutions。Six-way shuttle、Six Way Shuttle Solutions、High Density Storage Devices、Standardized Intelligent Devices、Intelligent Warehousing、Four-way shuttle、Automatic 3D warehouse