Constructing a Digital Twin Smart Warehouse Control Center

The smart park is modeled realistically to clearly demarcate various functional areas including warehouses, yards, roads, and buildings. It offers multi-perspective displays with the system supporting manual selection of display quality and automatic scene rotation.

Achievements

- Achieved a threefold increase in overall efficiency through the effective coordination of system software and hardware.

- Significantly enhanced warehouse space utilization and increased storage positions post-renovation.

- Realized unmanned operations, reducing personnel movement in and out of the warehouse, effectively ensuring a stable warehouse environment.

Zikoo's Solution

- Constructed a 575 sqm four-way vehicle stacker warehouse with a clear height of 6.5m, featuring a three-level storage system with over 600 storage positions.

- Equipped with 3 four-way shuttles, 1 elevator, multiple conveyor lines, telescopic belt machines, depalletizing robotic arms, and pallet stacker machines.

- Implemented a complete suite of WMS, WES, WCS, and RCS software systems.

- Standardized pallet size at 1300mm x 1100mm x 150mm.

Challenges

- Low efficiency in manual handling

- Poor utilization of warehouse space

- Numerous irregularly shaped columns in the warehouse

- High demands for environmental stability in storage

Project Background

Due to the unique nature of food products, including shelf life constraints, the food industry demands high accuracy in batch tracking. This necessitates warehouses and logistics to have enhanced timeliness and superior order processing capabilities. Furthermore, heightened safety and quality standards for food products, especially under the impact of the pandemic, have led to more stringent requirements for warehouse environments.

Real-Scene 3D Twinning of the Park

The smart park is modeled realistically to clearly demarcate various functional areas including warehouses, yards, roads, and buildings. It offers multi-perspective displays with the system supporting manual selection of display quality and automatic scene rotation.

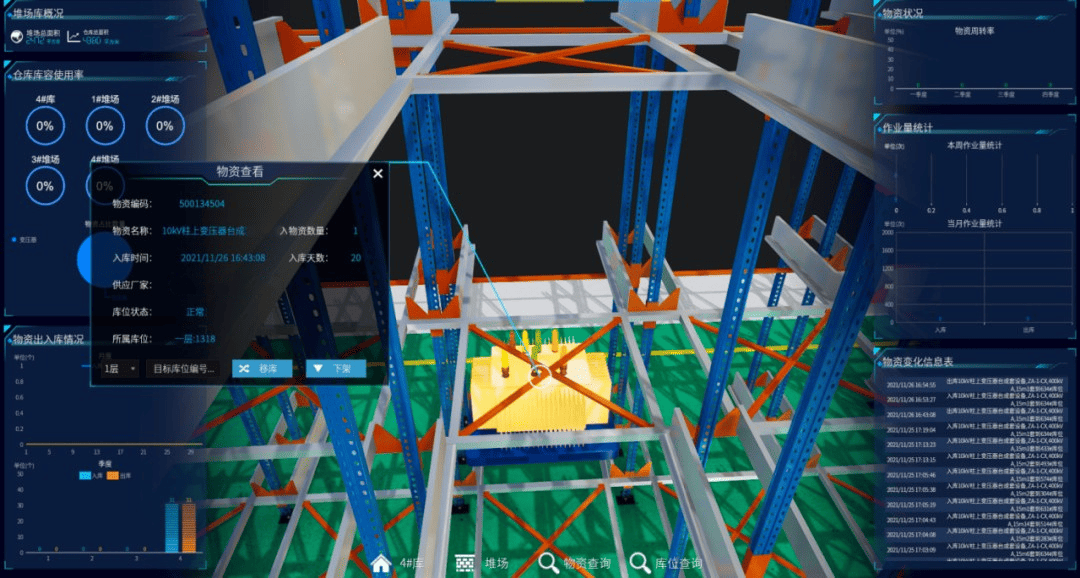

Real-Scene 3D Display Inside the Warehouse

Detailed 3D modeling of the warehouse interior includes walls, floors, roofs, vertical storage areas, and fire safety facilities, accurately reflecting the overall layout inside the warehouse.

Dynamic 3D Modeling of Moving Equipment in the Warehouse

A 1:1 scale 3D model of the moving equipment in the warehouse, including but not limited to zikoo Robotics’ proprietary four-way vehicles, unmanned forklifts, robotic arms, pallet dismantling machines, elevators, and conveyance equipment. The equipment’s dynamic movement is achieved through motion control algorithms and configurations, enhanced with high-definition rendering technology for superior overall presentation.

Multi-Source Data Integration

To accommodate the specific real-world scenarios of different clients, the system integrates data from on-site equipment and systems like WMS and WCS for data collection, achieving real-time synchronization between virtual and physical environments. Through digital twin screens and computers, users can adjust perspectives and switch scenes for real-time monitoring, enabling dynamic visualization of equipment, materials, alerts, and data.

Dynamic Visualization of Equipment

To ensure a smooth flow in the in-and-out storage process, the entire line utilizes a combination of digital twinning and simulation. Real equipment data drives the display of corresponding movements, including equipment coordinates, motion paths, and status alerts, for monitoring equipment status.

Visualization of Materials

A 1:1 model of the warehouse materials is constructed and bound to their codes, achieving real-time twin synchronization between the virtual and actual scenes. Through the digital twin monitoring and maintenance platform, data on goods being stored and dispatched can be displayed in real-time, offering comprehensive insights into the warehouse transfer activities for supervision, maintenance, and coordinated distribution.

Alert and Control Management

The digital twin system continuously gathers alert information and supports alert configurations, enabling notifications for stock shortages, inventory backlogs, and equipment alerts, prominently displayed on the information system’s homepage.

Virtual Reverse Control

The digital twin system allows for relocating and shelf management operations, achieving a true integration of virtual and physical elements with bidirectional control.

Data and Chart Displays

Integrated with the WMS system and connected to extensive warehouse data, the system presents various data types through bar graphs, line charts, pie charts, etc. Operational staff can understand the real-time situation of smart warehousing and goods without being on-site, making warehouse data real-time and transparent, thus enhancing storage efficiency.

Leveraging Emerging Technologies

Relying on big data, cloud computing, AI, IoT, and mobile internet, zikoo Robotics’ “Fly Shuttle Pallet Efficient Storage System” digital twin service makes warehouse operations visible in real-time, and materials manageable and controllable. It aids enterprises in digitally and intelligently upgrading their storage segments, reducing the difficulty and resource input of staff operations, and enhancing storage efficiency. Furthermore, by accessing, accumulating, and analyzing warehouse data for predictive analysis, it enhances the enterprise’s refined management capabilities, enabling scientific decision-making, making warehousing smarter, and industrial operations more intelligent.

Related Products

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-13851470374