How Does Zikoo Robotics Empower the Food Industry’s Dairy Giants to Take the Lead?

Due to the particularity of products, the food industry has high requirements for product batch attributes due to the limitation of product shelf life, requiring warehousing and logistics to have higher timeliness and stronger order processing capabilities.

Achievements

- Four-way shuttle car dense storage system, expand storage space upwards, increase warehouse capacityThe efficiency of material in and out of the warehouse is 90 ton/hour, improving the service level of material supply

- Intelligent and less-manned operation improves operation accuracy and reduces safety risks for operators

Zikoo's Solution

- The area of the four-way vertical warehouse is 1400㎡, the net height of the warehouse is 8.6m, and a 4-story three-dimensional warehouse is built, with more than 1400 cargo spaces

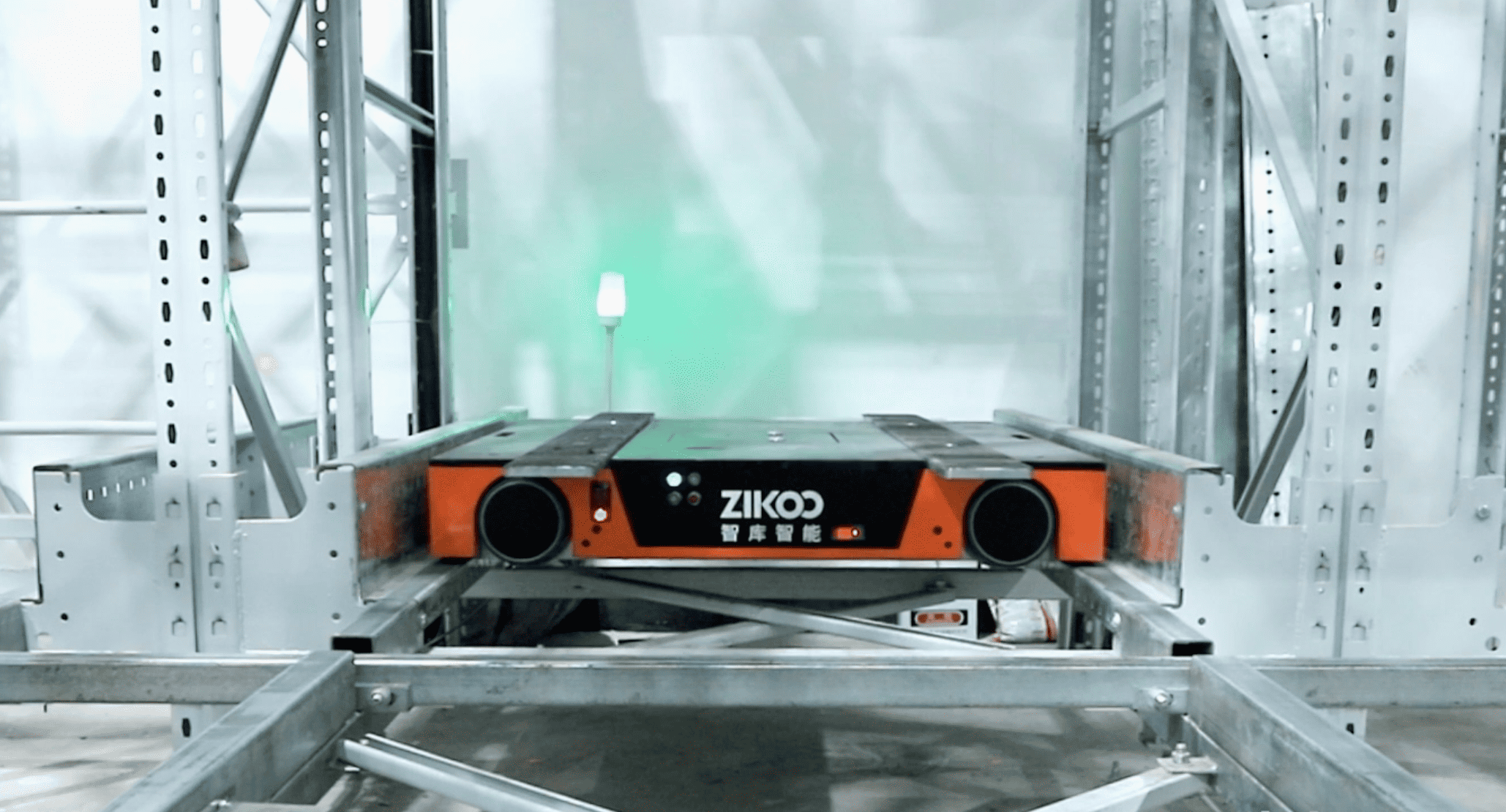

- 8 sets of four-way shuttles, 5 sets of elevators, 2 sets of shape testing equipment, 4 sets of fixed barcode readers, 1 set of WMS, WES, WCS, RCS software systems

- Pallet size 1500mm*1200mm*180mm, single pallet weight 1.2T

Challenges

- There are many columns and beams in the warehouse, and the site utilization rate is low

- The material storage period is short and the turnover rate is high

- High labor cost and risk of operation safety

Project Background

Due to the particularity of products, the food industry has high requirements for product batch attributes due to the limitation of product shelf life, requiring warehousing and logistics to have higher timeliness and stronger order processing capabilities. In addition, affected by the epidemic, food safety and quality standards have become more stringent, and higher standards and requirements have been put forward for the warehouse environment.

Industry Case Study

China, one of the largest food and beverage markets globally, has seen its market size grow annually with rising income and consumption levels. However, many domestic food and beverage enterprises still use traditional ground stacking methods, manual counting, and forklift operations, reducing storage and distribution efficiency while increasing operational and management costs.

The relatively short shelf life of food and beverage products demands higher requirements for product batch properties. How can warehousing and logistics become more time-efficient and better at handling orders? How to facilitate information exchange in the food industry’s logistical chain, ensuring smooth logistics and enhancing operational efficiency? These challenges are pressing issues for many food enterprises.

High-Efficiency, Dense Storage, and Flexible Expansion

Addressing these project pain points, Zikoo Robotics (ZIKOO), experts in pallet storage robotics, created a pallet four-way shuttle racking system. This high-rise warehouse, covering 1360 square meters with four levels and 1400 new storage positions, adopts a “high-efficiency, dense storage + flexible expansion” model. Dozens of intelligent four-way shuttles, high-speed elevators, and intelligent warehousing software (WMS, WCS, RCS) were deployed, achieving a flexible combination of “dense storage + pallet-to-person picking.” The project set new industry records, increasing warehouse operational efficiency by 180%, storage capacity by 300%, and reducing labor costs by nearly 40%, thus revolutionizing and upgrading the storage model in the dairy industry.

highly flexible four-way shuttle high-rise storage system

Zikoo Robotics customized five high-speed elevators to expand storage space upwards, addressing the factory’s original warehouse’s low space utilization due to numerous columns and beams. The elevators were placed in the gaps between beams, paired with 1,6-depth shuttles, maximizing storage units while fully utilizing the limited warehouse area, tripling the original storage capacity.

The finished goods RGV transports products from the production line to the warehouse’s inbound docks. In coordination with the elevators, goods are transported to designated layer junctions. Dozens of four-way shuttles in the warehouse move flexibly in all directions within the racks, unimpeded by space, ensuring efficient storage and handling of goods.

Revolutionizing Warehouse Management

The dairy enterprise’s storage cycle is shortened, turnover rate increased, and high-frequency loading and unloading. The high-rise warehouse adopted Zikoo Robotics’ proprietary intelligent warehousing software, enabling large-scale four-way shuttle cluster dispatching for efficient and flexible operations. For instance, to address congestion at junction points inside the warehouse, the system adopts an “island” strategy, designating junction points as “island” areas, planning new road combinations to rationalize vehicle entry and exit sequences, reducing unnecessary avoidance. Compared to traditional storage methods, Zikoo Robotics’ shuttles’ discrete operation ensures continuity in goods handling and storage, significantly improving equipment operational efficiency by 180%.

With Zikoo Robotics’ highly flexible four-way shuttle high-rise storage system, the dairy enterprise achieved smart, minimally manned warehouse operations, enhancing operational precision. Goods storage and retrieval no longer require manual operations but are carried out automatically by four-way shuttles and elevators, reducing safety risks for workers. Additionally, the construction of the four-way shuttle high-rise warehouse enabled centralized storage, unified control, and standardized management of goods, further strengthening intensive materials management, maximizing the use of storage facilities, and enhancing the enterprise’s centralized control capability over materials.

In the future, Zikoo Robotics will continue to provide high-efficiency, high-density, flexible, low-cost intelligent warehousing solutions for various industries. By leveraging core technologies and hardware/software products, Zikoo Robotics aims to drive more enterprises towards smart logistics transformation and upgrading.

Related Products

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-13851470374