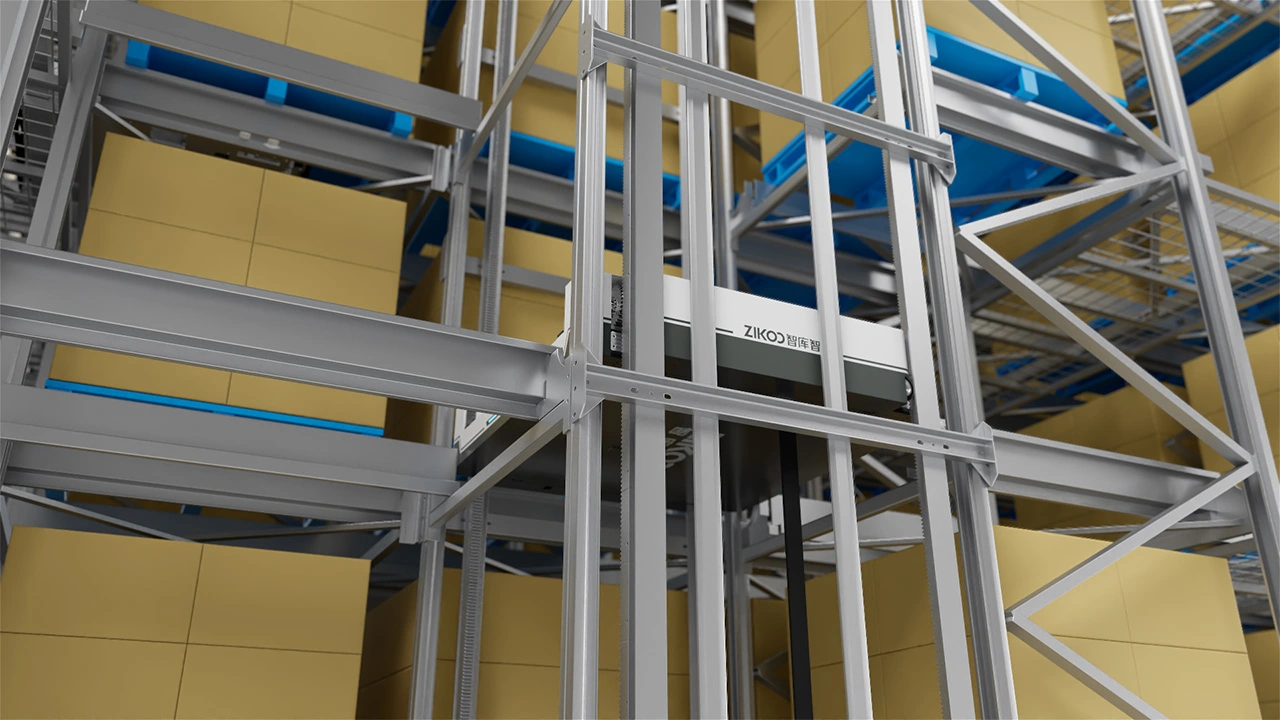

r-bot+h-bot

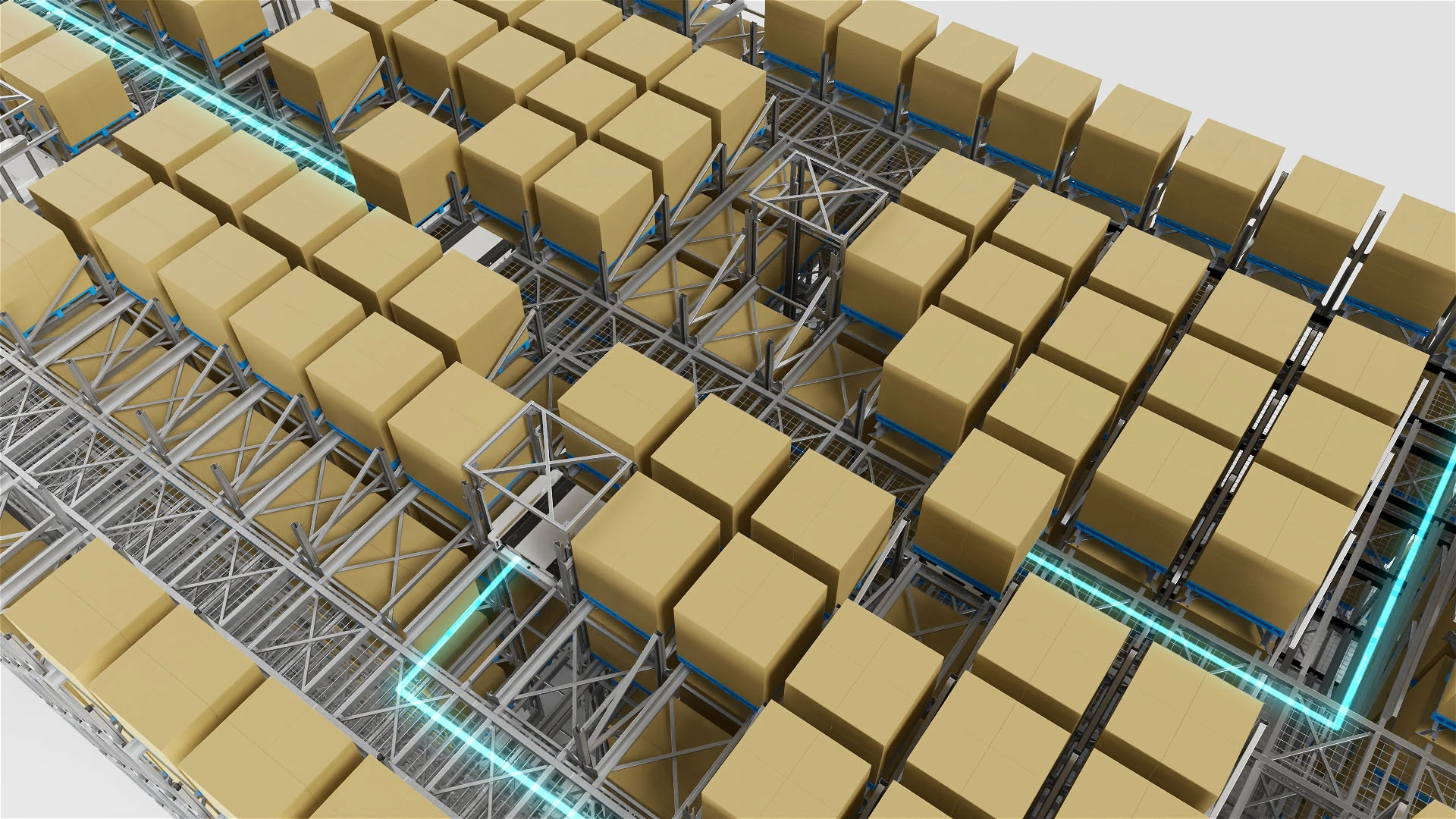

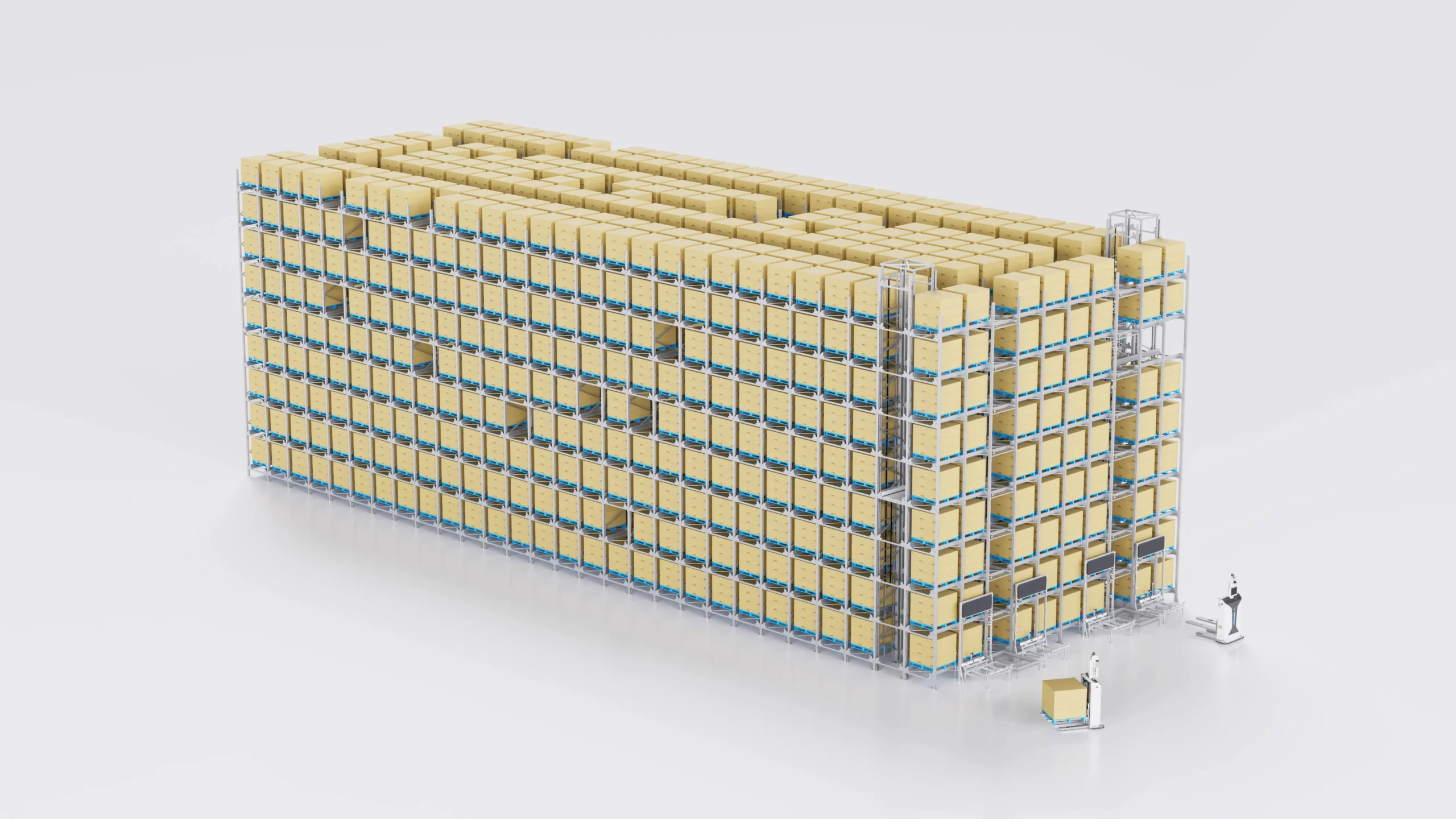

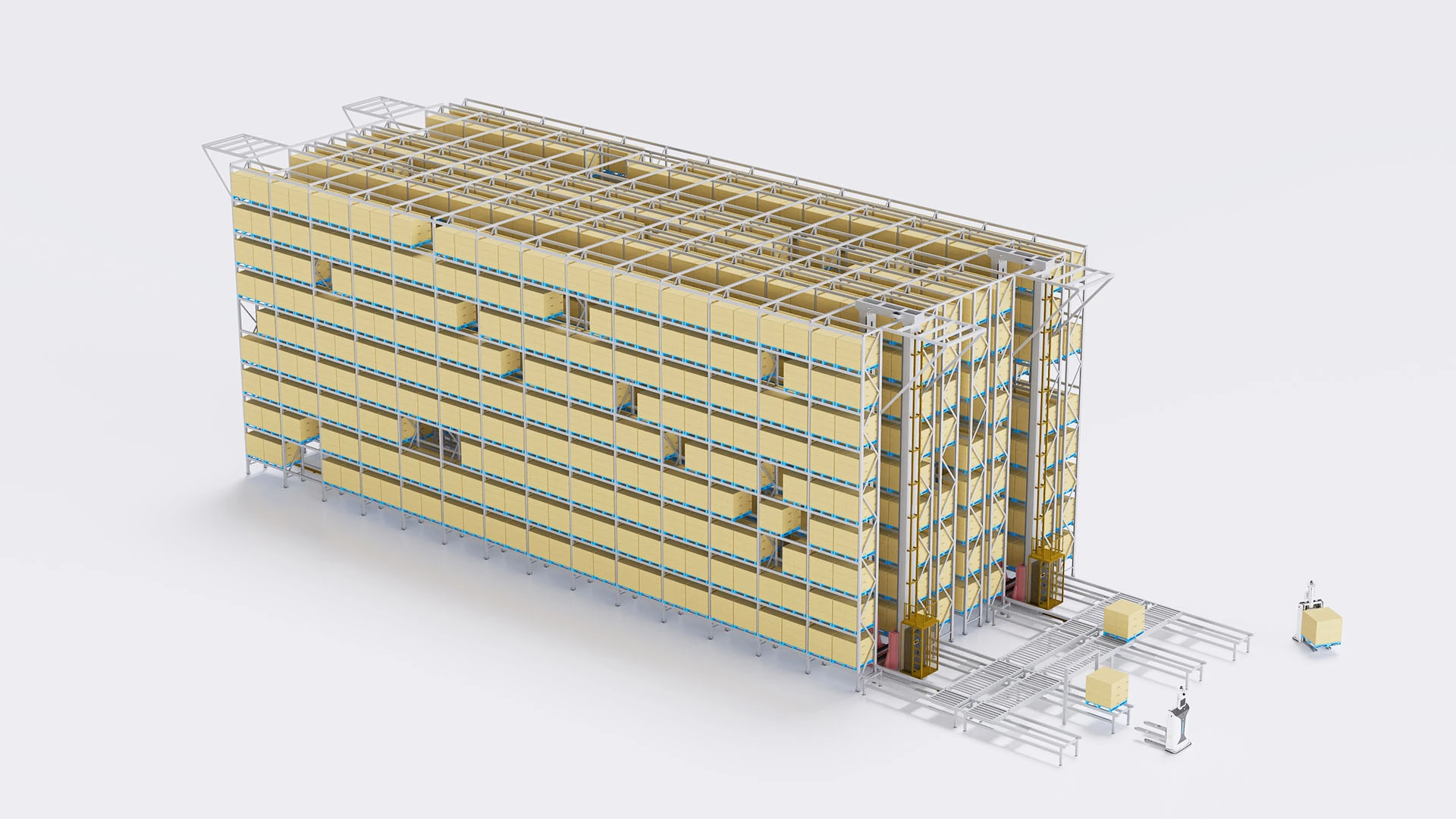

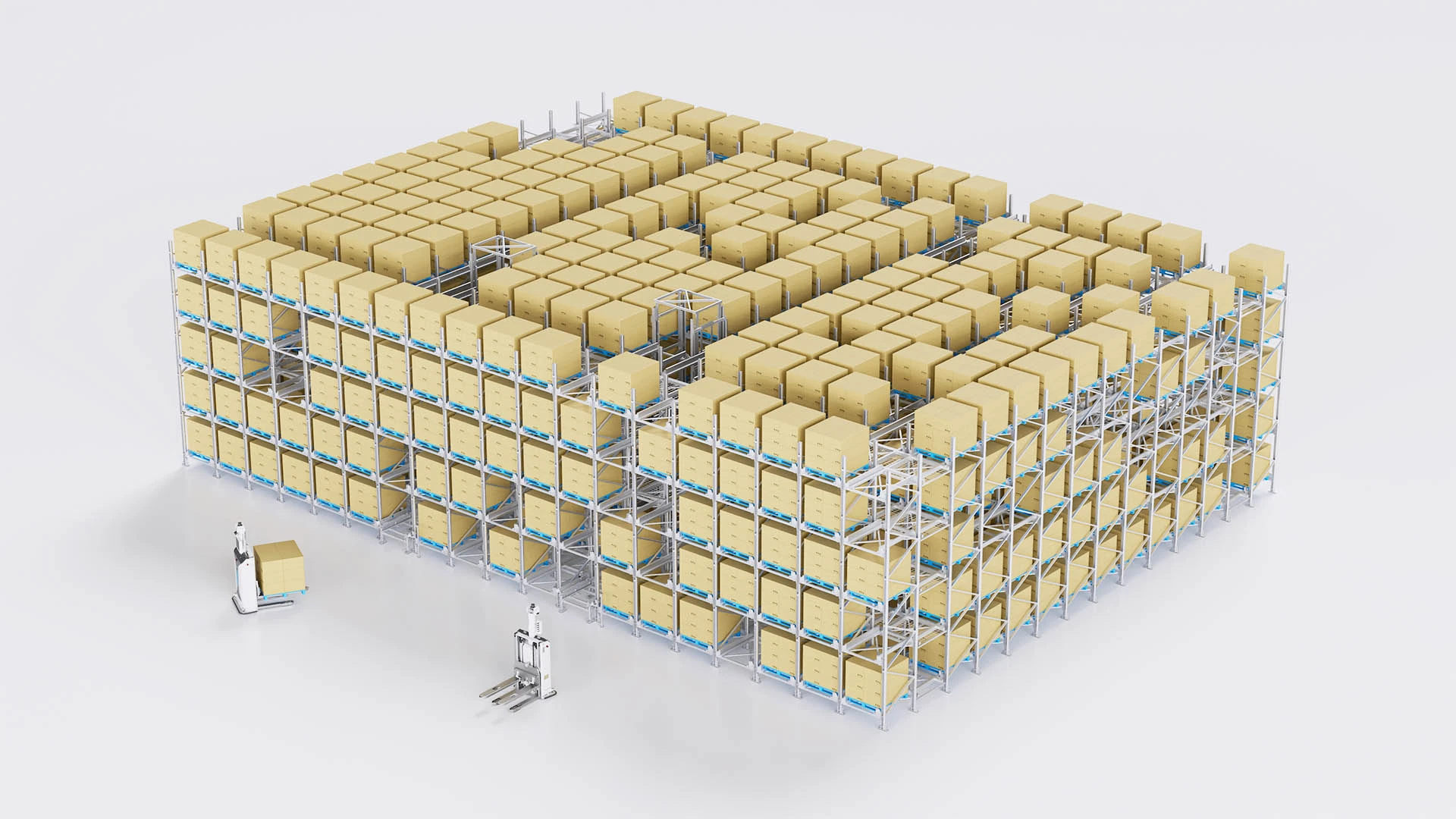

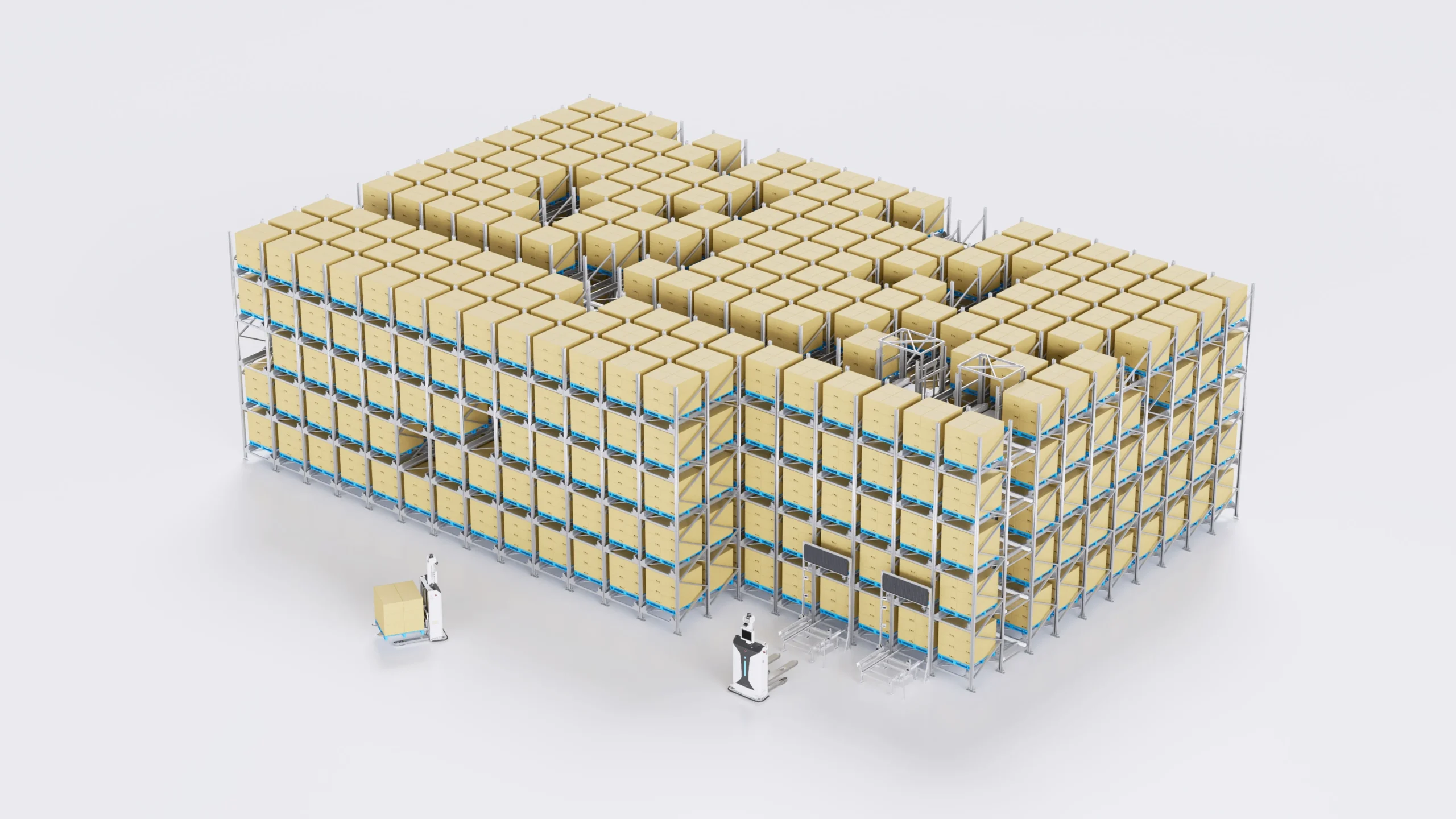

Six-Way Shuttle Dense Storage System

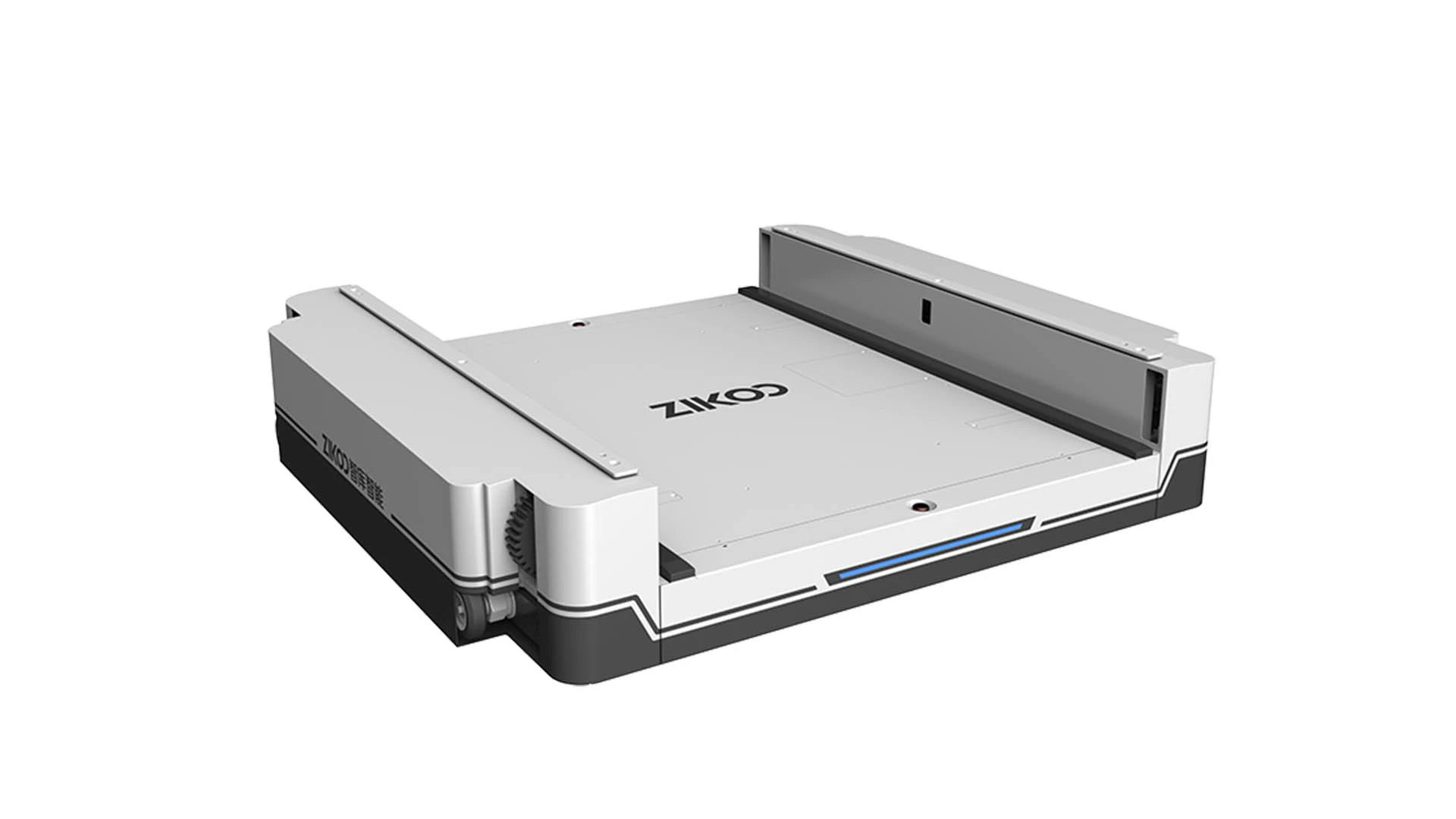

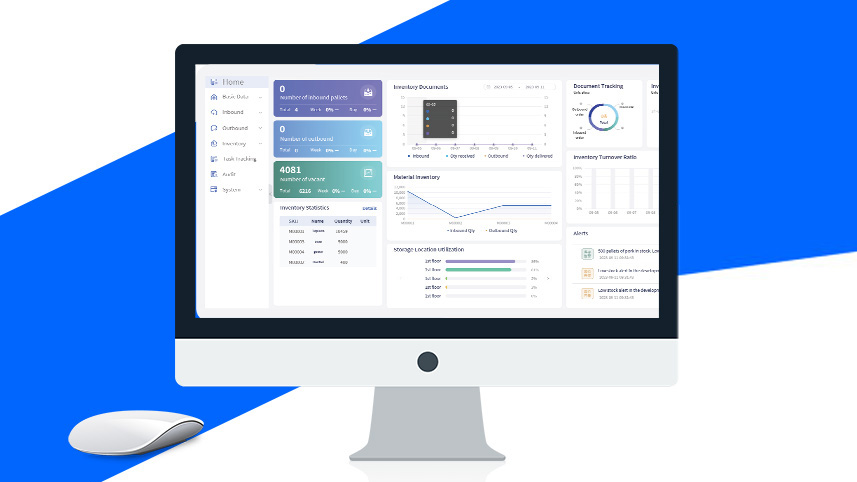

The innovative combination of R-bot four-way shuttle and H-bot vertical two-way shuttle is suitable for dense storage scenarios of whole pallet inbound and outbound or a small amount of picking inbound and outbound, with significant advantages in cost, efficiency and density. H-bot can be deployed flexibly at any position inside or outside of the warehouse, with even efficiency configuration, fast delivery and easy maintenance, which is the best choice for customers who are in pursuit of the maximum storage density and inbound and outbound efficiency.

The Advantages of R-bot+H-bot Six-Way Shuttle Dense Storage System

The innovative combination of the R-bot four-way shuttle and the H-bot vertical two-way shuttle enables six-way shuttle movement in space. It allows flexible deployment at any position inside and outside of the warehouse, ensuring balanced efficiency, fast delivery, and easy maintenance. Compared to stacker crane warehouses, four-way shuttle + lift warehouses, and shuttle board warehouses, it offers significant advantages. This solution is ideal for industries that prioritize storage, such as food, manufacturing, cold chain, energy, chemicals, and building materials.

High Efficiency

- Comprehensive efficiency increase of 2-3 times compared to traditional warehouses, and 15%-20% compared to general automated three-dimensional warehouses (Stacker Cranes AS/RS).

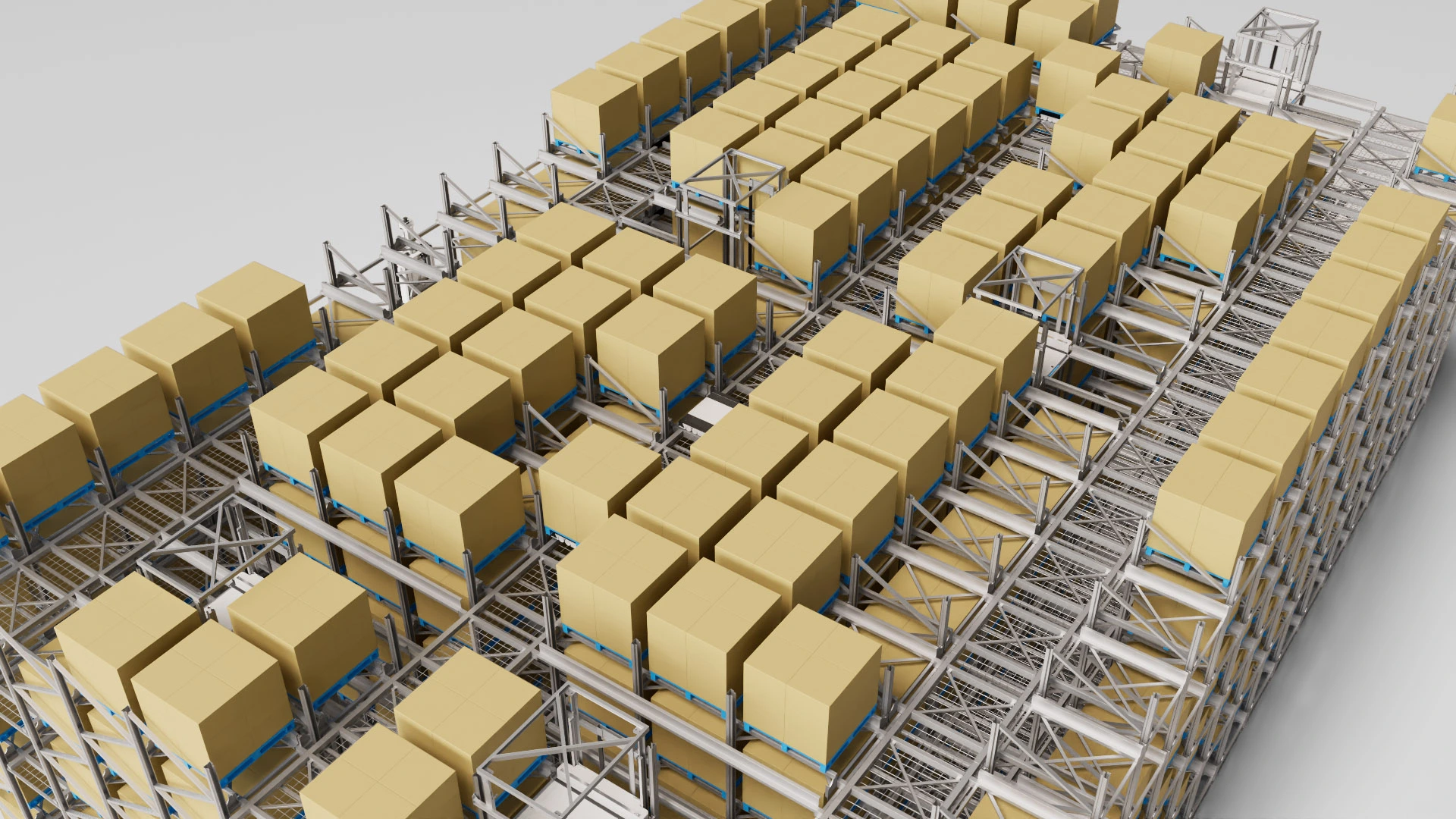

High Density

- Replacing the traditional lifter and conveyor line, the vertical two-way shuttle only occupies one warehouse space, occupying more than 80% less space than the hoist, and the space in front of the warehouse can be planned for more spaces, with a higher space utilization rate.

High Flexibility

- Suitable for new or remodeled storage scenarios, according to the site, flexible planning of storage space; according to SKU, flexible planning of deep space; according to the efficiency, flexible planning of caching space.

Quick Delivery

- Standardized products, no electrical debugging, installation is delivery, delivery cycle shortened by more than 80%, delivery costs significantly reduced.

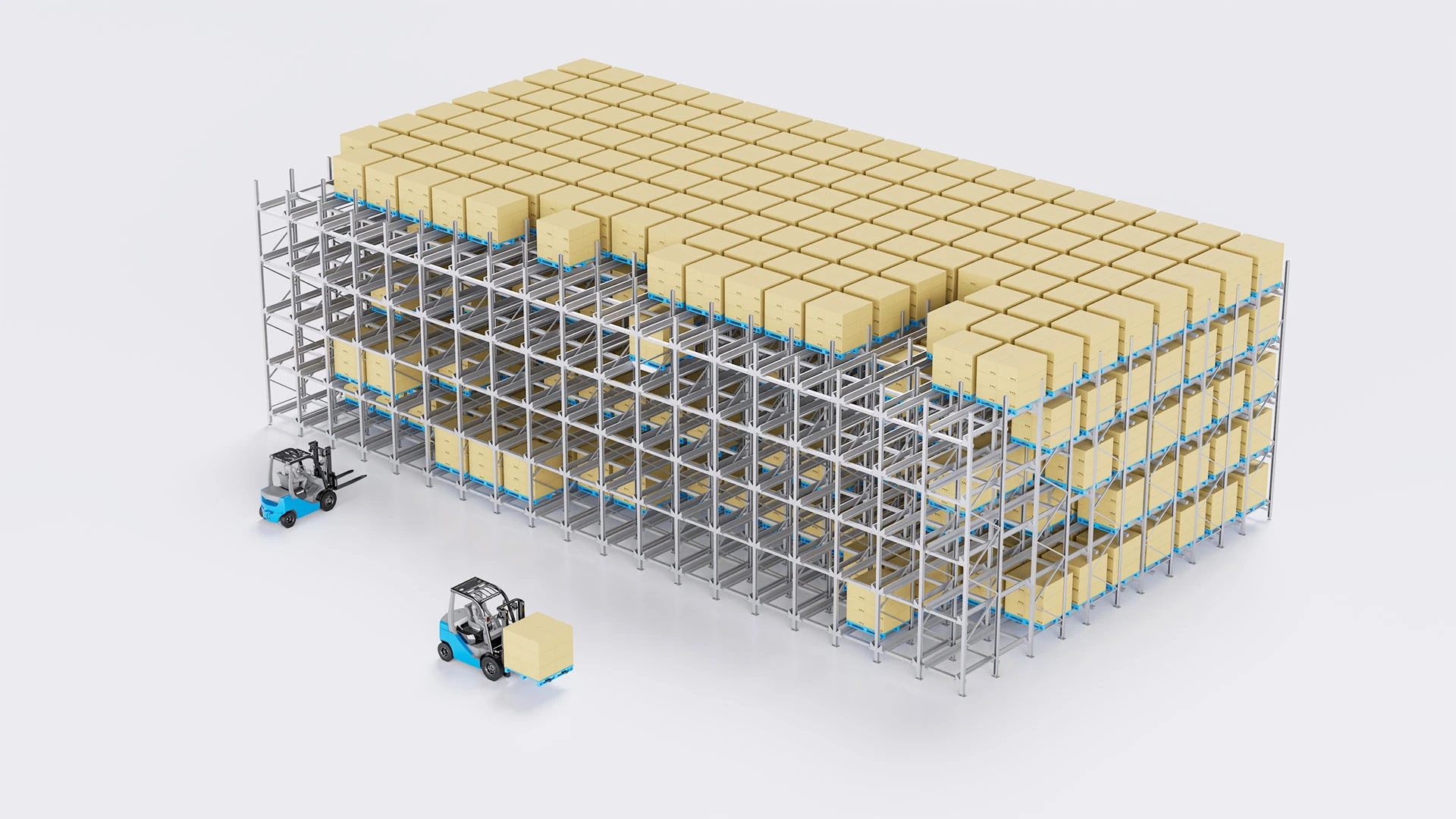

Program Comparison

Six-way Shuttle Warehouse vs. Stacker Crane Warehouse

Six-way Shuttle warehouse vs. Four-way Shuttle Warehouse

Six-way Shuttle Warehouse vs. Manual Shuttle Panel Warehouse

Applications

Scenarios

Industries

Composition

Connect with our experts to receive customized robotics solutions

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-13851470374