u-bot+amr

Narrow aisle picking system

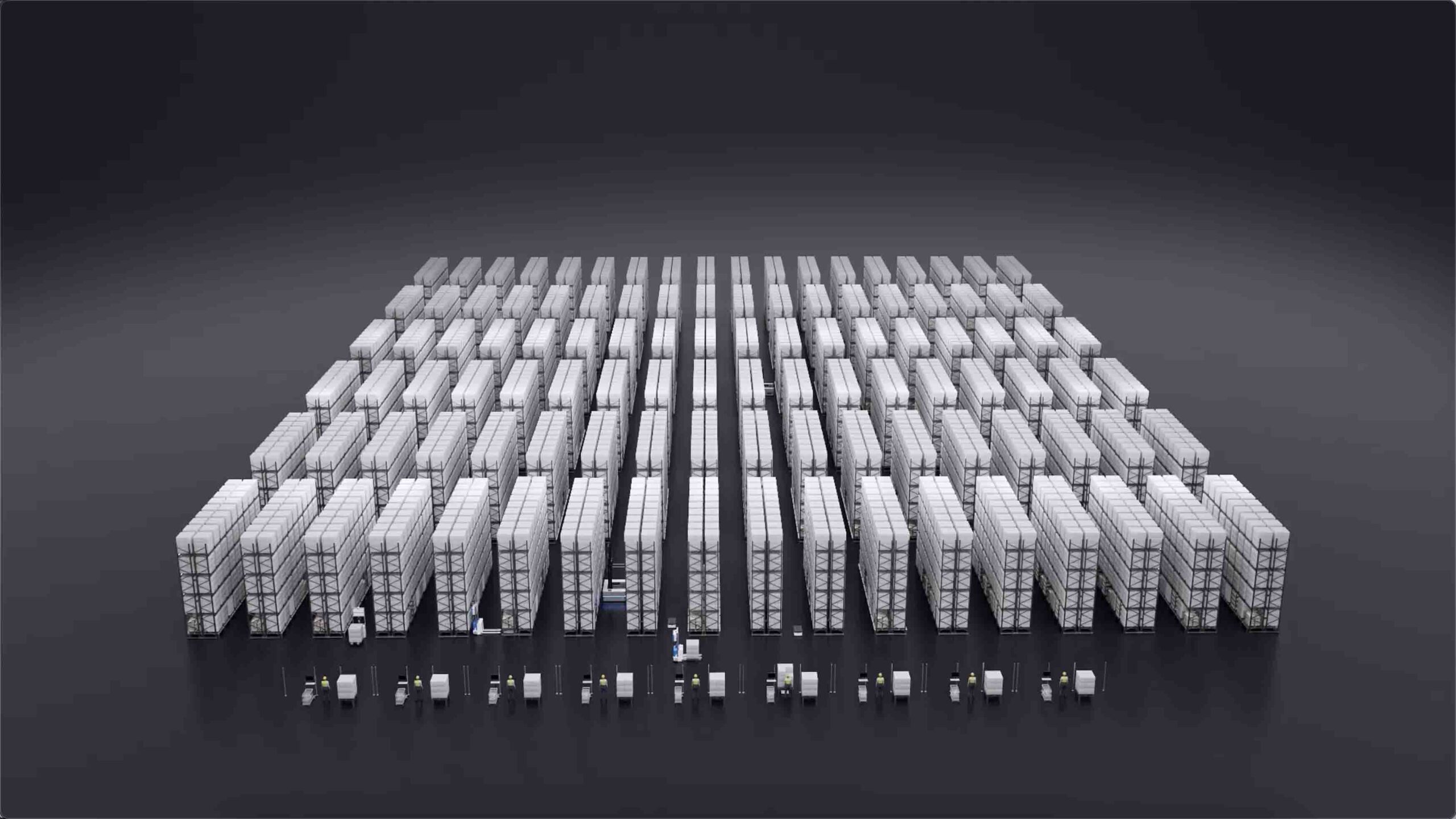

The narrow aisle picking system composed of U-bot + AMR can realize the efficient cooperative operation of “up-storing and down-slowing” and “up-storing and down-picking”, which can be combined with multifunctional workstations to meet the needs of large, medium and small pieces of the whole category of picking out of the warehouse, and can also be connected to the production line by the AMR. It can also be docked to the production line by AMR to flexibly cope with various operation scenarios. Through PTP intelligent warehousing software, it can realize intelligent scheduling of multiple vehicles and greatly improve the comprehensive efficiency.

U-bot+AMR Narrow Aisle Picking System

U-bot+AMR Narrow Aisle Picking System adopts U-bot Omnidirectional Stacker Robot and AMR Handling Robot to work together, matching with beam shelves to realize efficient cooperative operation of “up-stocking and down-slowing”, “up-stocking and down-picking” and “up-stocking and down-picking”. “It can be used with multifunctional workstations to meet the needs of large, medium and small pieces of all categories of picking out of the warehouse, and can also be docked by AMR to the production line, so as to respond flexibly to various operational scenarios. Compared with the U-bot narrow aisle storage system, the efficiency of access and picking is greatly improved. Through the PTP intelligent storage software, it can realize the intelligent dispatching of multiple vehicles, and the comprehensive efficiency is greatly improved.

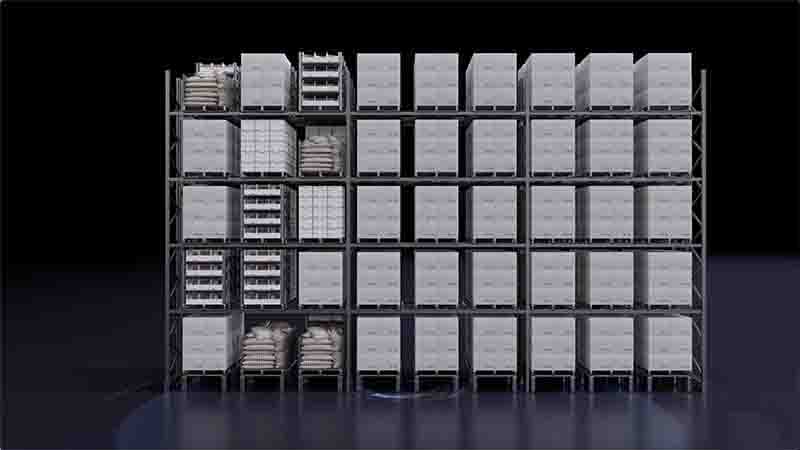

Ultra High Storage Density

- Extremely narrow driving lanes of 2.1m, dramatically improving lateral space utilization

- Lifting height 0-8m, greatly improving the utilization of longitudinal space

- Realize co-location storage and one-stop picking of small, medium and large pieces, standard/non-standard goods.

Ultra-high operating efficiency

- No-unpacking shelf picking for more customer needs

- U-bot high and low level handling for efficient pick and place.

- AMR in-stock and out-of-stock handling, efficient in and out of the warehouse

Ultra-high ROI

- 1-2 year payback period

- Compatible with To B palletizing and To C picking.

- Conversion of traditional manual forklift warehouses without replacing shelves

Flexible deployment

- Flexibility to increase or decrease the number of robots according to order requirements

- Global planning, step-by-step implementation, upgrading without stopping production

- Supports multiple navigation methods and adapts to changing environments

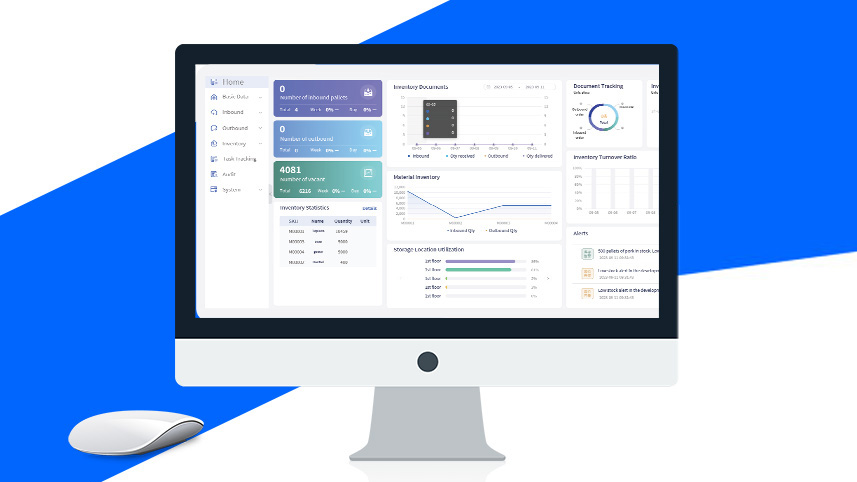

Composition

In Action

Inbound

Outbound

Features and Benefits

Data Simulation

-

Net size of warehouse: L60m*W20m*H10m

-

Product mix: U-bot*2, AMR*4

-

Number of cargo spaces: 1616

-

Applicable SKUs ≤ 10,000

-

Efficiency in and out of the warehouse ≥ 80 trays / hour

-

Picking efficiency ≥ 300 pieces / hour

-

Investment: 1 million +

Contact us for customized smart warehousing solutions

Applications

Scenarios

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-13851470374