On March 6, ZIKOO ROBOTICS unveiled its revolutionary Six-way shuttle system, marking a new milestone in smart warehousing. The Six-way shuttle manufacturers have designed this innovative solution to address critical challenges in pallet storage, enhancing efficiency, density, and flexibility.

Breaking Industry Limitations

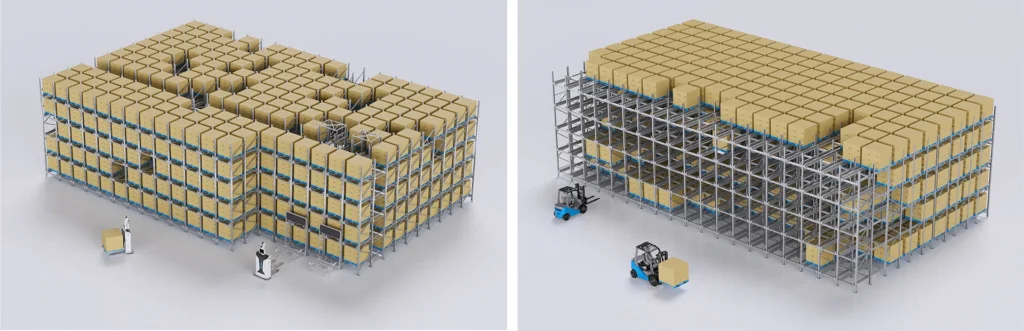

Traditional solutions like Four-way shuttle, stacker crane, and shuttle board systems face constraints in space utilization and order response speed. In contrast, the Six-way shuttle redefines “pallet-to-person” operations with robotic intelligence.

- Plug-and-Play Installation: No electrical debugging, reducing delivery time by 80%.

- Maximized Space Utilization: Occupies 80% fewer slots than elevators.

- Cost-Effective: Eliminates conveyors and lifting mechanisms, cutting structural costs by 30%.

- Upgraded Four-way Shuttle: Gearbox structure for durability, RFID + magnetic sensors for ±1mm precision.

- Smart Software Integration: Real-time digital control, seamless coordination with AS/RS warehouse automation.

Versatile Application Scenarios

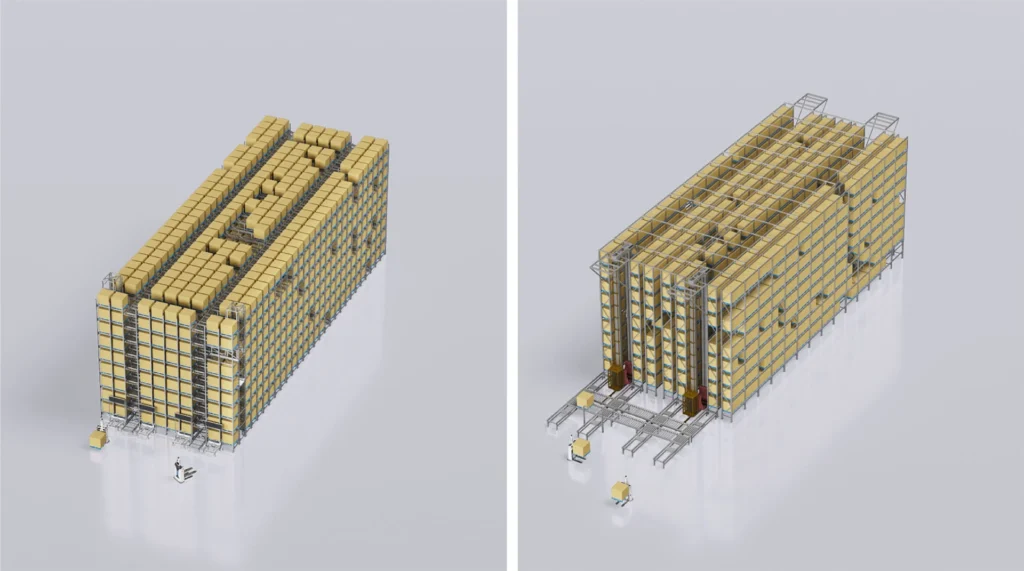

1.Dense Storage Solution

The Six-way shuttle integrates Four-way shuttle (R-bot) with two-way vertical H-bot, achieving full-space mobility. It surpasses stacker crane systems in flexibility and efficiency, ideal for industries like food, cold chain, and manufacturing.

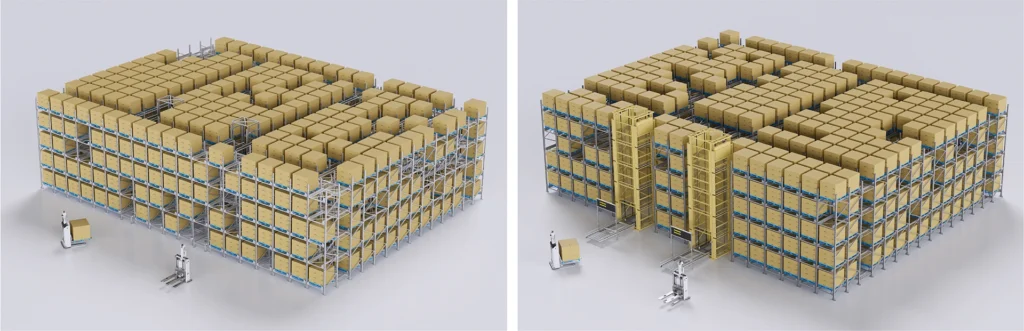

2.Storage & Picking Solution

Optimized for asrs warehouse and smart warehousing companies, this solution reduces movement distance and enhances order fulfillment for e-commerce, retail, and 3PL industries.

ZIKOO ROBOTICS’ ecosystem—featuring WMS, RMS, and RCS—completes a next-gen warehouse automation package, ensuring a seamless transition into the intelligent logistics era.

Keywords:

Four-way shuttle,Six-way shuttle manufacturers,stacker crane,smart warehousing companies,asrs warehouse