H-bot

Vertical Two-Way Shuttle

Standard type | American type | Janpanese type| Heavy load large pallet type

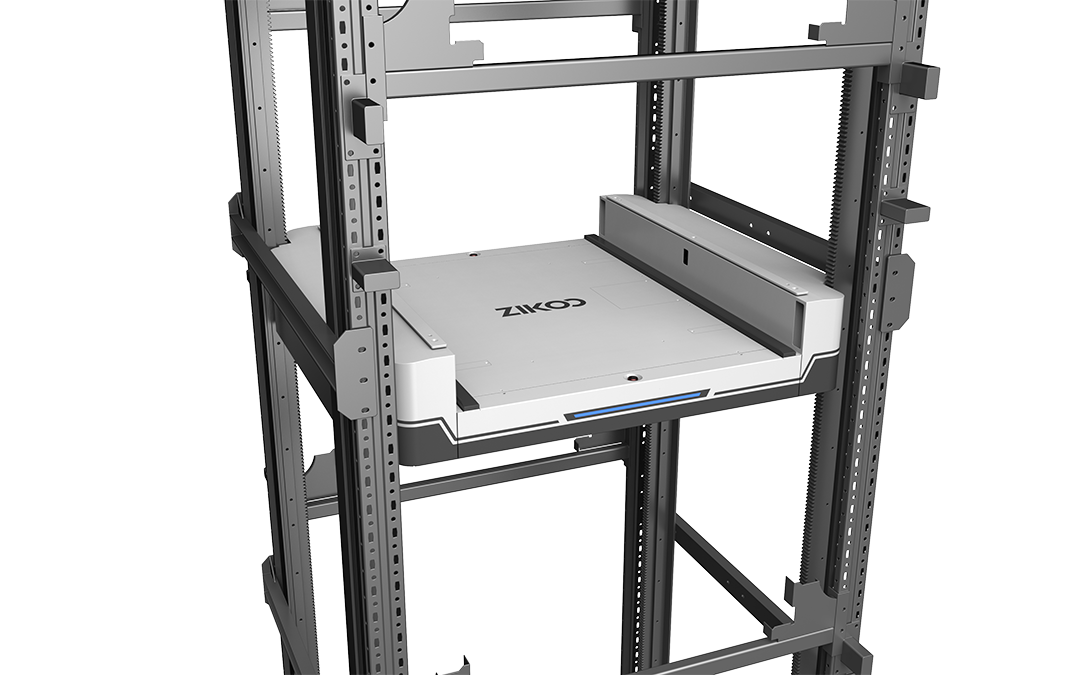

H-bot vertical two-way shuttle is an intelligent warehouse robot designed for “pallet to person” dense storage, storage-picking scenario, with vertical lift, flexible layout, fast delivery and other advantages, and R-bot four-way shuttle seamless synergy, to realize the space of six-way shuttle driving. It replaces the traditional elevator and conveyor line in the elevator, and is a comprehensive upgrade product for space utilization and cost reduction.

1800 KGRated load |

-25℃-45℃Applicable temperature |

1m/sMax lifting speed |

±1 mmPositing accuracy |

Technological Innovation

Streamlined design

Platform and modular design for high reliability

Scene Adaptation

Covering temperature environments from -25℃ to 45℃,and adapting to a variety of pallet sizes

Extreme speed

Empty load speed 1m/s, full load speed 0.3m/s

Empty load acceleration 2m/s², full-load acceleration 0.3m/s²

Ultimate space

Occupies only 1 cargo space for better space utilization

Accurate positioning

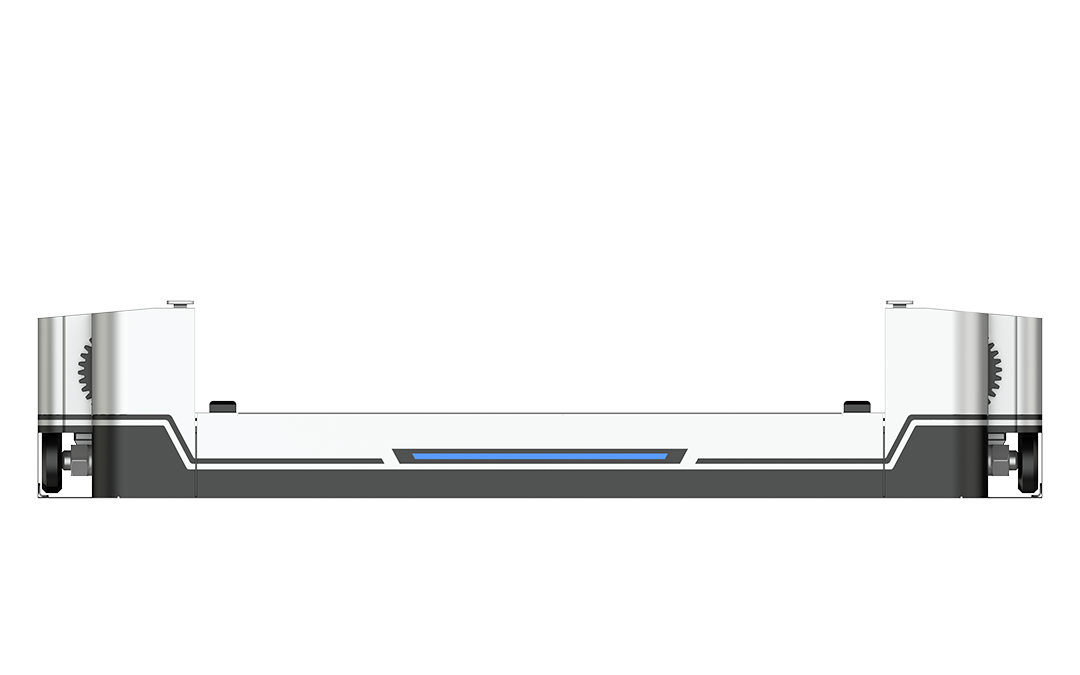

Rack and pinion drive, positioning accuracy ±1mm

Flexible Planning

Flexible deployment in any location inside or outside of the warehouse

Safety Protection

Multi-protection, electrical interlocks, overrun detection

Fast delivery

Dramatically reduced lead times with standard products delivered as soon as they are installed

Product Values

New Solution

Combined with the four-way shuttle , it becomes the all-new six-way shuttle

New Scenarios

Suitable for both high-density storage and picking-storage integration scenarios.

New Form

Replaces the elevator, no electrical debugging required, safe and reliable.

New Intelligence

Software-driven hardware, enabling remote delivery.

Advantage Comparison

Standardized product design, shorten the delivery cycle by more than 80%,

delivery cost is greatly reduced.

The outer frame borrows the rack column piece, the product cost is more than

30% lower than that of the elevator.

Occupying only one pallet position, reducing the number of

occupied spaces by more than 80%.

It can be deployed either embedded in the warehouse or external inside of

warehouse, which makes the program layout more flexible.

H-bot vertical two-way shuttle product parameters

Model

Body weight

Body size

Rated load

Applicable pallet

Applicable temperature

-

Kg

mm

Kg

mm

℃

H1800B

345

L1300*W1464*H288

1800

1200*800~1200

-25~45℃

H1800A

325

L1300*W1332*H288

1800

1016*1219

-25~45℃

H1800J

335

L1300*W1392*H288

1800

1100*1100

-25~45℃

Customization

Customization

Customization

Customization

Customization

Customization

Positioning accuracy

Empty/full load speed

Acceleration

mm

m/s

m/s²

±1

1/0.3

2/0.3

±1

1/0.3

2/0.3

±1

1/0.3

2/0.3

Customization

Customization

Customization

Total power

Control mode

Transmission mode

KW

-

-

16

Servo

Rack and pinion

16

Servo

Rack and pinion

16

Servo

Rack and pinion

Customization

Customization

Customization

Certificate type

-

Contact Us

Zikoo Robotics

Contact ZIKOO Robotics automation experts and learn how we can increase your operating efficiency and increase storage density.

Address

4F, Building 4, No. 170-1 Software Avenue, Yuhuatai District, Nanjing, China

Phone

(+86)-13851470374