In the ever-evolving landscape of intelligent warehousing, the four-way shuttle has emerged as one of the most revolutionary innovations in pallet storage automation. Often seen as an upgrade from earlier shuttle technologies like shuttle boards and alphabet shuttles, this system plays a central role in the modern Four-way pallet shuttle warehouse, offering high-density, modular, and flexible solutions for complex storage needs.

What Is a Four-Way Shuttle?

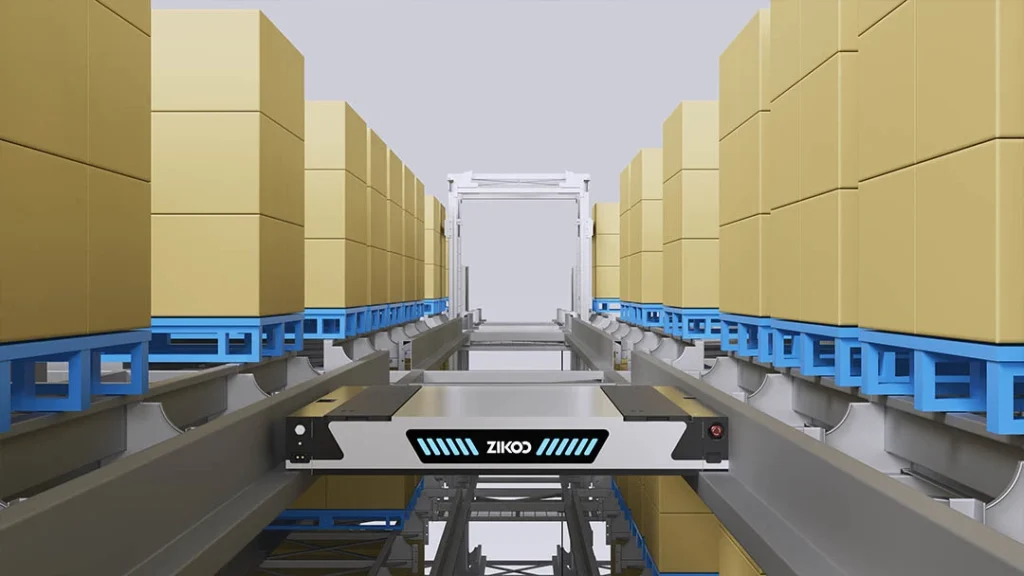

A four-way shuttle is a robotic unit designed to navigate freely along both the horizontal and vertical axes—forward, backward, left, and right—within an automatic three-dimensional warehouse structure. It is commonly paired with reciprocating lifts for vertical movement, creating a dynamic, scalable, and highly responsive storage system.

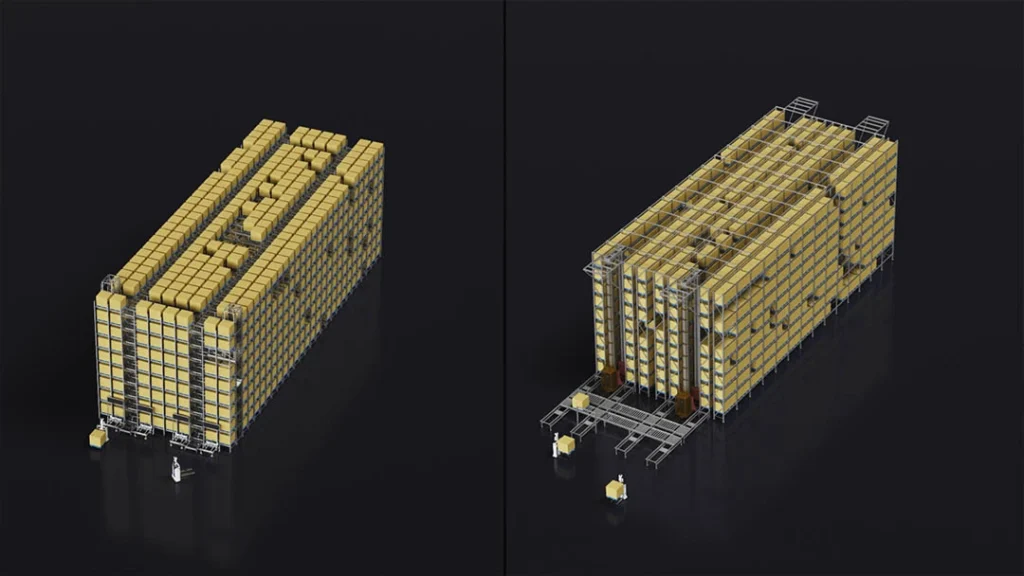

Compared to traditional stacker crane systems (also known as stacker crane storage), four-way shuttle solutions provide superior adaptability in environments with irregular layouts, lower ceiling heights, or variable throughput requirements. These characteristics make it ideal for industries with demanding storage scenarios and limited warehouse space.

Key Advantages Over Stacker Cranes

1.Modular Scalability

Businesses can increase or decrease the number of shuttles based on changing throughput needs—ideal for seasonal demand or phased investments.

2.Superior Flexibility

Four-way movement allows seamless adaptation to non-linear warehouse designs and zone expansions.

3.High-Density Intelligent Storage

By maximizing horizontal and vertical space, the system supports dense, multi-layered pallet storage in a compact footprint.

Current Challenges in the Market

Despite the rapid adoption of four-way pallet shuttle warehouse systems, there are industry-wide challenges to be addressed:

·Track Compatibility & Stability

Since shuttles operate on racks, inconsistencies in track manufacturing between shuttle vendors and rack suppliers can cause operational friction. At Zikoo Robotics, we solve this by offering end-to-end systems—including proprietary racks and shuttle rails—to ensure seamless performance.

·Vehicle Reliability

Some brands focus too heavily on lightweight designs, speed, or battery endurance, compromising long-term stability. At Zikoo Robotics, product durability and field-tested reliability are non-negotiable.

·Multi-Shuttle Scheduling

As more shuttles operate on the same layer, traffic management becomes critical. Poor task coordination can result in operational bottlenecks. Zikoo’s proprietary RMS ensures optimized task allocation, reducing vehicle idling and “traffic jams.”

�� The Zikoo Advantage

As a trusted name among intelligent warehousing manufacturers, Zikoo Robotics leads the way in delivering reliable, integrated, and scalable four-way shuttle systems. Our solutions are:

·Fully modular for progressive upgrades

·Designed as complete intelligent storage ecosystems

·Backed by CE/UL certifications for global markets

·Seamlessly integrated into ERP, WMS, and MES platforms

We build more than an automated warehouse—we build future-ready infrastructure for intelligent logistics.

Conclusion

The four-way pallet shuttle warehouse represents the next chapter in high-density, flexible intelligent storage. Though still evolving, its rapid rise highlights a clear market shift away from conventional stacker crane storage. As challenges are addressed through technical refinement and system integration, the future of warehouse automation belongs to agile, modular systems like Zikoo’s.

Zikoo Robotics: Engineering the next generation of intelligent warehousing—one shuttle at a time.

Keywords:

Four-way shuttle,Four-way pallet shuttle warehouse,Intelligent Warehousing,Automatic three-dimensional warehouse,stacker crane ,Intelligent Storage